jschoolcraft

Member

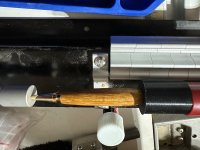

A bunch of Designer Twist (no tenon variety) pens from PSI wrapped in a bunch of different wood, no idea on most of it. Some really nice chatoyancy on some.

Finishing:

- Sanded 120-600

- Quick wipe with alcohol

- Mylands Cellulose Sanding Sealer

- Doctor's Woodshop Pen's Plus (just one application)

- Renaissance Wax

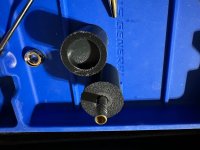

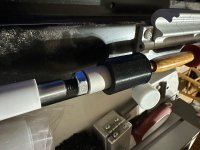

Now, onto the 3d printed transmission jig that made assembly a treat. I used it on every one of those pens and they all came out perfect extension.

This was heavily inspired by others:

- A Quick Tip for Seating Transmissions by Bob Swartzendruber seems to be the source for most of these.

- Mark Dyer demonstrates this in 10 Minutes to Better Pen Making - Assembly.

- Dave (@egnald) made very cool jig described in this thread: https://www.penturners.org/threads/press-perfect-jig.178095/#post-2189931

So, you press the transmission in with the jig, then I flipped the whole assembly around to press in the tip while the transmission was still protected in the jig. Worked great.

Things I might do differently (or suggest someone else to do differently):

- Make the entire diameter bigger so the shallow recess fits both press fittings

- Remove the shallow recess altogether and just let the surfaces meet on the press fittings

- Print it with an embedded magnet and then you might be able to accommodate both a 13/16" depth and swap in a drill rod like Dave has to set the 1 3/4" depth for the other style pens (or make that's 6 of one, 1/2 dozen of the other)