monophoto

Member

A recent post about depth gauges suggested that a discussion of shop-made depth gauges might be useful.

I made mine from a scrap of ash, a few bits of walnut, a length of 1/8" brass rod, and a thumb-screw and matching hex nut salvaged from a Harbor Freight F-style clamp that had given up the ghost. The thumbscrew and nut I used are likely metric, but as long as they match, the actual threading is irrelevant.

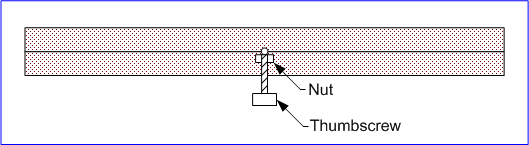

I started by drilling a 9/64" hole for the brass rod through the center of the ash billet. Then, I sawed the billet in half lengthwise with the saw kerf centered on that hole. I drilled a second hole perpendicular to that 9/64" hole through one of those halves; the diameter of this hole was sized to be slightly larger than the OD of the threaded shank of the thumbscrew. Then, using a Forstner bit, I enlarged that hole to create a cavity that was large enough in diameter and depth to receive the nut with the nut remaining flush with the top of the wood. After epoxying the nut into the hole, I glued the two halves of the ash blank back together so that the nut was embedded inside the blank. Finally, I mounted the blank on the lathe and turned it round and tapered the ends. After light sanding, I applied my BLO and wax finish. With the rod passing through the 9/64" hole, the thumbscrew can pass through its hole and nut to trap the rod to set the desired turning depth.

To make the gauge a bit more fancy, I turned a couple of knobs from scraps of walnut that I epoxied onto the ends of the brass rod.

Some variations that might be considered:

I made mine from a scrap of ash, a few bits of walnut, a length of 1/8" brass rod, and a thumb-screw and matching hex nut salvaged from a Harbor Freight F-style clamp that had given up the ghost. The thumbscrew and nut I used are likely metric, but as long as they match, the actual threading is irrelevant.

I started by drilling a 9/64" hole for the brass rod through the center of the ash billet. Then, I sawed the billet in half lengthwise with the saw kerf centered on that hole. I drilled a second hole perpendicular to that 9/64" hole through one of those halves; the diameter of this hole was sized to be slightly larger than the OD of the threaded shank of the thumbscrew. Then, using a Forstner bit, I enlarged that hole to create a cavity that was large enough in diameter and depth to receive the nut with the nut remaining flush with the top of the wood. After epoxying the nut into the hole, I glued the two halves of the ash blank back together so that the nut was embedded inside the blank. Finally, I mounted the blank on the lathe and turned it round and tapered the ends. After light sanding, I applied my BLO and wax finish. With the rod passing through the 9/64" hole, the thumbscrew can pass through its hole and nut to trap the rod to set the desired turning depth.

To make the gauge a bit more fancy, I turned a couple of knobs from scraps of walnut that I epoxied onto the ends of the brass rod.

Some variations that might be considered:

- I chose to glue a 1/8" layer of walnut between the two halves of the ash billet, and then drilled the hole for the rod through this walnut layer. However, that step is only for esthetics and isn't functionally necessary.

- If it is necessary to purchase a thumbscrew and matching nut for this project, using a T-nut with the head embedded in a recess centered in the blank rather than a hex nut would reduce the risk that the thumbscrew might inadvertently get backed out too far and get lost.

- I made my depth gauge for use in judging the depth of bowls and boxes, and the turned walnut nob on the end prevents the rod from scratching the bottom of those turnings. That knob will interfere with using the gauge to judge the depth of small-diameter blind holes, so if that is the objective, that knob could be omitted.

- The ideal length of the turned portion of the gauge should be enough to span the opening of boxes or bowls if that is the intended purpose.

- Coat-hanger wire could be substituted for the brass rod. Most of the coat hangers I have measured use 3/32" steel wire.