Wmcullen

Member

I'm not sure if this process is right or wrong; unique or common. But I want to share in case it's interesting. |

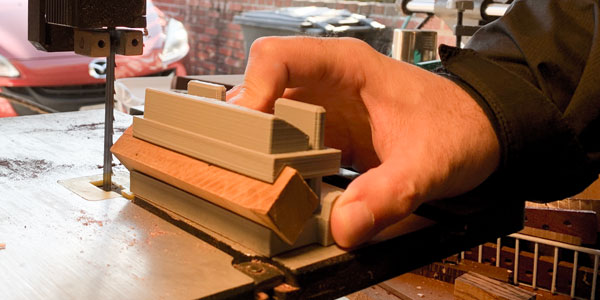

28: Cutting Corners with Bandsaw

last post- 27: Customized Zero Clearance Bandsaw Peg Jig

(3d *.obj file attached)

Tony mentioned he uses his bandsaw to remove corners from brittle blanks before turning.

We started talking about developing a simple 3d printed blank holder.

The Problemlast post- 27: Customized Zero Clearance Bandsaw Peg Jig

(3d *.obj file attached)

Tony mentioned he uses his bandsaw to remove corners from brittle blanks before turning.

We started talking about developing a simple 3d printed blank holder.

Cutting a blank at 45 degrees freehand feels like a fast way to have a problem.

Our Solution

(Not rocket surgery.)

Print a v-grooved sled to hold a squared blank and keep our fingers further away from the cutting.

The jig accommodates square blanks from 5/8" to 1". It is intended for rough cuts. Precision is not one of its traits.

*Optional Stop Block Attachment

We designed an extra piece that can be CA glued to the bottom of the jig and used in conjunction with a 1" wide x 0.25" tall stop block (not provided). This way the sled would glide along without having to eyeball the cut.

3D Model

Attached is an obj file called CornerShave4.obj

The model is provided as-is. A bandsaw blade will go through this plastic like a hot knife through butter. I never rely on printed plastic for protection. I only use this to keep my fingers far away from the blade.

Thanks for looking!

- Cullen