Hello Everyone.

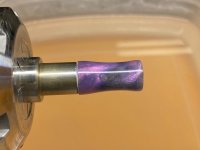

Here are two pictures of a kitless section that I am working on. At first, this looked like a void to me, but the rectangular shape has me doubting that. I did hit it with a little ultra thin CA between the two pictures and it feels solid when I run a fingernail or hobby knife blade over it.

Any suggestions on how to fix it?

I'm not sure that I want to try to dig it out and fill with CA, but maybe that would be best.

I can always make a new section from some other contrasting material, but I really want to keep the continuity of the gradient of the rod intact if possible.

Thanks in advance for your help!!

.

.

Here are two pictures of a kitless section that I am working on. At first, this looked like a void to me, but the rectangular shape has me doubting that. I did hit it with a little ultra thin CA between the two pictures and it feels solid when I run a fingernail or hobby knife blade over it.

Any suggestions on how to fix it?

I'm not sure that I want to try to dig it out and fill with CA, but maybe that would be best.

I can always make a new section from some other contrasting material, but I really want to keep the continuity of the gradient of the rod intact if possible.

Thanks in advance for your help!!

.

.