workinforwood

Member

I bought this machine from China a few months back. It's actually been working great until last week. Although I like the machine, the 4 axis is junk, always has been. It will cut a part perfect but if you break a bit and raise machine, change bit then do a restart it will lose so much steps going back to zero zero zero that the part is destroyed. But as long as there's no interruptions all is good so could get by with it for now.

But...then on Friday about 9 days ago, a part I was cutting was all mangled up. I noticed the 4 axis making a weird noise. It was clicking while turning. When I removed the stepper motor, plugged it back in, I noticed it isn't rotating. When I press Y, the stepper just shutters. So I assume motor went bad. I order a new motor from China and express shipping because I need this fixed quick. I install new motor, plug it into machine, all excited, I press Y button, damn thing shutters! I fiddle with the rotary, everything seems fine, pull motor back off, press y, the motor shutters.

So there must be a problem before the motor. The control board is shot?

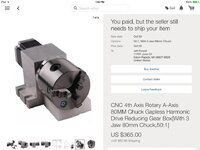

After buying new motor I also bought a new 4 axis, a better one that when it arrives I was just planning to plug it in and adjust my Mach settings. The new one I bought is 50:1 ration hyperdrive or something like that, much better than this 6:1 gear belt drive set up. Now I guess it will need a new control board?

Any suggestions on what's going on?

But...then on Friday about 9 days ago, a part I was cutting was all mangled up. I noticed the 4 axis making a weird noise. It was clicking while turning. When I removed the stepper motor, plugged it back in, I noticed it isn't rotating. When I press Y, the stepper just shutters. So I assume motor went bad. I order a new motor from China and express shipping because I need this fixed quick. I install new motor, plug it into machine, all excited, I press Y button, damn thing shutters! I fiddle with the rotary, everything seems fine, pull motor back off, press y, the motor shutters.

So there must be a problem before the motor. The control board is shot?

After buying new motor I also bought a new 4 axis, a better one that when it arrives I was just planning to plug it in and adjust my Mach settings. The new one I bought is 50:1 ration hyperdrive or something like that, much better than this 6:1 gear belt drive set up. Now I guess it will need a new control board?

Any suggestions on what's going on?