RobS

Member

Hi Guys

This is a work in progress, more pictures to come.

*****The information in this posting is intended for member use, if you find a flaw in the design or an improvement, please let me know and I will update the model and print and re-post. This was done in Solidworks2014, if you'd like the native file PM me with an email address.*****

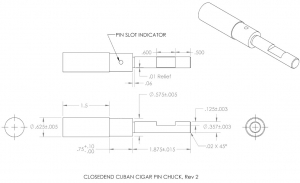

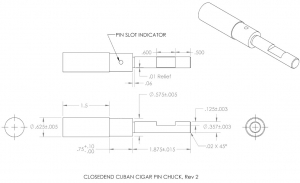

So I've been dying to make a Closed end Cuban Cigar Pen. However I could not find a pin chuck that would work for what I wanted. So I drew up the attached drawing and Rick (rherrell) was kind enough to custom make this for me at a nominal fee (well worth it).

Please note it was designed to be used with a Beal Chuck with a 0.625 collet.

The one thing to note, is that the chuck has been designed with the bushing built in, so you would turn your blank down to the shoulder which has already been machined to the correct diameter. I'm sure one day I'll beat it up too badly to use, then I would have the shoulder turned down and another separate collar bushing turned and installed. However, I like not having more parts to lose, so I went with the permanent shoulder.

This baby just came in, so I have not had a chance to make anything yet.

However, the fit and finish is awesome.

View in Gallery

View in Gallery

Thanks

This is a work in progress, more pictures to come.

*****The information in this posting is intended for member use, if you find a flaw in the design or an improvement, please let me know and I will update the model and print and re-post. This was done in Solidworks2014, if you'd like the native file PM me with an email address.*****

So I've been dying to make a Closed end Cuban Cigar Pen. However I could not find a pin chuck that would work for what I wanted. So I drew up the attached drawing and Rick (rherrell) was kind enough to custom make this for me at a nominal fee (well worth it).

Please note it was designed to be used with a Beal Chuck with a 0.625 collet.

The one thing to note, is that the chuck has been designed with the bushing built in, so you would turn your blank down to the shoulder which has already been machined to the correct diameter. I'm sure one day I'll beat it up too badly to use, then I would have the shoulder turned down and another separate collar bushing turned and installed. However, I like not having more parts to lose, so I went with the permanent shoulder.

This baby just came in, so I have not had a chance to make anything yet.

However, the fit and finish is awesome.

View in Gallery

View in Gallery

Thanks

Last edited: