PTJeff

Member

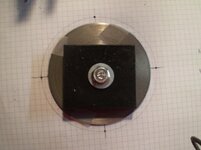

I finally got my metal lathe up and running. Turning square stock to round requires a 4 jaw chuck and the independent adjustable jaws was just too much work (later i found out it was busted.) So I bought a self centering 4jaw. I also had to buy an adapter plate. These are blanks, you have to turn and face to fit your new chuck. Well I generally consider myself a wood turner, now I have to turn metal...feel the adrenalin pump through my head. Lot of reading and questions with alot of help from members of this community, especially Joe S., I have succeded in turning this blank to fit my new chuck. Turning cast is a dirty job, there are no curls of metal, just smelly grit. The next big hurdle is to drill holes in blank to secure chuck.