JD Combs Sr

Member

I recently saw a couple posts about problems with On/Off switches so I thought I would post some pics of a recent change-out of the On/Off switch for my 2Hp Jet 1642. I am pretty sure the procedure will work for the 1.5Hp Jet 1642 as well as some of clones such as the Grizzly G0632 and G0698. I believe there is also an older Laguna lathe that was also a clone of the Jet. In any case if what you see here looks like your lathe On/Off switch then the procedure should work for you.

FIRST THING I DID WAS - UNPLUG THE LATHE

I then removed the switch mounting plate from the lathe.

I disconnected three(3) wires from the On/Off switch, a yellow to the left(bottom) and a blue and a white to the right(top) of the switch.

There is no need to remove the actuator knob, it is not likely to be the problem. As long as it can be snapped in and out and it stays in place it is probably OK.

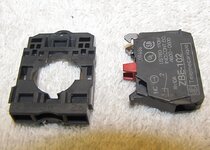

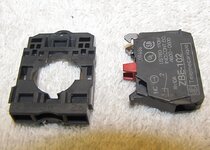

By inserting a small Philips screwdriver into a small slot and prying slightly on the release mechanism I released the switch "base"(my terminology) from the actuator.

The actual switch is attached to the switch base by a spring loaded hook mechanism. A small flat bladed screwdriver inserted into a slot in the mechanism and a slight prying releases the switch from the base.

With the hook released the switch will tilt up and out of the base.

(will continue in the next post)

FIRST THING I DID WAS - UNPLUG THE LATHE

I then removed the switch mounting plate from the lathe.

I disconnected three(3) wires from the On/Off switch, a yellow to the left(bottom) and a blue and a white to the right(top) of the switch.

There is no need to remove the actuator knob, it is not likely to be the problem. As long as it can be snapped in and out and it stays in place it is probably OK.

By inserting a small Philips screwdriver into a small slot and prying slightly on the release mechanism I released the switch "base"(my terminology) from the actuator.

The actual switch is attached to the switch base by a spring loaded hook mechanism. A small flat bladed screwdriver inserted into a slot in the mechanism and a slight prying releases the switch from the base.

With the hook released the switch will tilt up and out of the base.

(will continue in the next post)