qquake

Member

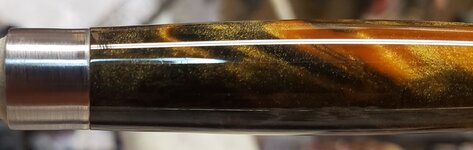

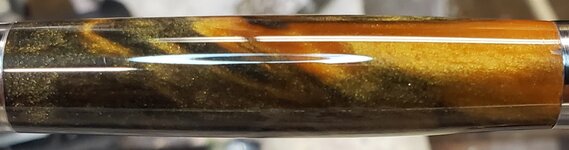

I get a decent polish on my acrylic blanks, but if you look close, there are always micro scratches. I tried some buffing pads my detailing friend uses, but they weren't any better. So I decided to try lambskin chamois. I figured if it's good enough for a Ferrari, it should be good enough for a pen, right? If anything, it left worse scratches. My regimen is wet sand to 500, then Novus 3, Dr. Kirk's, PlastX, and finally Meguiar's swirl remover. Could speed have anything to do with it? I usually turn and polish at 2000 rpm. Slower? Faster?