robutacion

Member

Hi everyone,

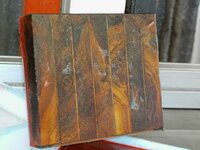

Some here will know that I produce lots of timbers that are perfectly suitable for casting, some are known as "worthless blanks" others as "Mutts", etc. I didn't really wanted start casting but I just can't throw those pieces away or burn them, some and due to the cracks and flaws on them, display the best colours and grain out of the whole log or even tree so I had to do something about it.

I decided to try doing them myself following the recommendation provide by Curtis, in his PDF format file with a detailed description of how to go about it, including how to make the molds. Got myself a pressure pot and all the other stuff needed and in no time I was ready to pour...! that's when my problems started (in relation to casting, off-course...!:wink , not being in contact with these sort of chemicals (PR) for over 20 years, I didn't realize how bad of a reaction I would have, exposed to them so, as soon as I got the first batch in the pot, I started getting nasty headaches that wouldn't go away.

, not being in contact with these sort of chemicals (PR) for over 20 years, I didn't realize how bad of a reaction I would have, exposed to them so, as soon as I got the first batch in the pot, I started getting nasty headaches that wouldn't go away.

The next day when I open the pot, I nearly went to the Moon and back, with the vapors hitting me like a 20 pound slash hammer...! I start coughing, farting and carry on, my eyes were watering and my nose was running, wow... what in the heck was that...?? I though!

I start coughing, farting and carry on, my eyes were watering and my nose was running, wow... what in the heck was that...?? I though!

My head was trying to separate from my shoulders with pain, and I had to get out of there (the shed where I was, open door and a big gap between the shed was and the ceiling (ventilation).

After a few deep breaths I went back in, grab the 12 individual molds and come outside, still under cover but with no walls on two sides. Got the blanks out of the molds and put then to dry 10 meters away from the shed, hopping the smell would go away but it didn't, for over a week the only think I could smell was the PR curing...! I then, resized the casted blanks and decide to make another batch and see what would happen. Not a lot of difference from the first pouring experience really, so I decided that, for whatever the reason, I was getting a much worse reaction to this stuff, then I would ever expect. It should be mention that, in my early working career, I had 2 chemical intoxication from chemical vapors inhalation (a certain type of spraying sanding sealer, and rolled floor wood varnish!)

Contacted various members already casting, offering the exclusivity of my woods supply for their castings, as I didn't wanted to create a business "clash" among our friends casting members. One of those contacted did accept trying them, so I automatically rejected any other offer to supply these woods to anyone else!

I actually thought in selling all the casting gear after I finished with the resin I had, and was no shortage of interest particularly with the 12 molds and the wood tray to separate the molds inside the pressure pot, so I was satisfied that I would get some of my money invested in this operation as I had someone buying my woods for casting, I was happy that I didn't need to do them myself.

The attempt to have my woods used by this casting friend, didn't really work as we both expected so, was obvious that it would be a long time if ever before this friend would run out of the 20kg of timbers supplied, and in a conversation we both had, this was obvious. I was suggested for to sell them to anyone (another major casting member) that wanted to use it, was no need to keep the "exclusivity", which I accepted as reasonable.

In conversation with someone living in this town, I was told of a fellow that did work in a fibro-glass factory, the factory closed some time ago and this fellow lost his job so, I went and saw him. Was evident this fellow (John) wasn't a very healthy person, his face was as dry as a bone and he looked 20 year older than what he was (47). After a short conversation he accepted to do all my castings at his place, I would supply everything and give him an idea what I wanted to have done.

Once again I was satisfied that I had someone doing this for me, someone that spend 25 years working with these type products. Once a week I would visit him and get what was done at least one week prior as I found that the first few days of the blanks coming out of the pot, the smell is a lot stronger.

He made me about 200 blanks and a few weeks ago is just passed away with a massive heart attack...!:frown: poor John!

Got all my gear back, paid what was owed to the wife (no kids) and went home a bit distressed with all this. Recently I decided to get myself a good chemical mask (double crystal filters) and start to do them myself as the wood was start pilling up a lot more than I wanted. The mask does seem to do a good job (expensive but efficient), and the sensitivity to the lightest of the PR smells, seems also to be improving.

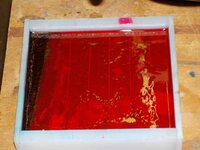

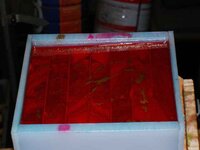

A few days ago I decided to make new molds to make things a bit easier and faster, using a lot less resin (wasting less), and increase the run (pot capacity) of blanks done, from 12 to 21 (blanks @ 21mm square x 130mm long). I wanted to show everyone that wants to do casting or are already playing with it that, these newer molds will make the casting per blank more economical.

I will start to list here and on eBay very soon of my casted blanks, and with all due respect to all that invented the names for the casted blanks and sells them, well know here and elsewhere, I don't particularly like the name of "worthless" (sorry Curtis!) as I don't like to call "left overs" to the off-cuts I get from initial cuttings either, so my casted blanks, regardless if they are 1%, 50% or 99% resin/wood, will be called, "RESIFILL" blanks, and will be supplied with the four square corner cut out!:wink::biggrin: Not to mention that most of the woods used are not found in any other casted blank anywhere in the world, and anyone that wants to cast and don't have the wood blanks, I will sell you as much as you want/can afford and sent anywhere...!

I would gladly stop casting myself, but unless I sell this type of woods, regularly and in reasonable amounts, I will be casting more and more to catch up with the volume of suitable timber I got stored. There is obviously the extra expense of all the colours other materials and accessories, like plenty of acetone, and off-course the main ingredient the PR resin with catalizer. A 1 gallon of resin just doesn't last long but I get a fair number of blanks done!

My intention with this extra work I'm doing now is to firstly, recover whatever the blank sale price I would sell if was not "flawed" in some way, secondly recover the expense involved with all the casting products by calculating on average on many blanks I make out of a gallon of resin, adding and equal amount for all the colours, filling/effect powders, acetone, demolding agents, containers, mixers, gloves, etc., etc., etc., $1 each for labor, 10ct each for electricity and 10ct each for equipment investment. This has come to a grand total of $...!, well...that will be reveled the day I put the first groups on sale at proper forum location. The only variation in prices are the different costs for the few timber species that are a little more expensive than my normal $1 per blank. The price per blank itself will be the same if sold as a full wood pen blank, PLUS the casting costs already determine by constant testing, explained above!

Don't worry, my Resifill blanks will be "surprisingly" economical...! promise.:wink:

Update completed.

Now here they are, a "few" pics..! Yes..., it did happen...!

pics..! Yes..., it did happen...!

Cheers

George

Some here will know that I produce lots of timbers that are perfectly suitable for casting, some are known as "worthless blanks" others as "Mutts", etc. I didn't really wanted start casting but I just can't throw those pieces away or burn them, some and due to the cracks and flaws on them, display the best colours and grain out of the whole log or even tree so I had to do something about it.

I decided to try doing them myself following the recommendation provide by Curtis, in his PDF format file with a detailed description of how to go about it, including how to make the molds. Got myself a pressure pot and all the other stuff needed and in no time I was ready to pour...! that's when my problems started (in relation to casting, off-course...!:wink

The next day when I open the pot, I nearly went to the Moon and back, with the vapors hitting me like a 20 pound slash hammer...!

My head was trying to separate from my shoulders with pain, and I had to get out of there (the shed where I was, open door and a big gap between the shed was and the ceiling (ventilation).

After a few deep breaths I went back in, grab the 12 individual molds and come outside, still under cover but with no walls on two sides. Got the blanks out of the molds and put then to dry 10 meters away from the shed, hopping the smell would go away but it didn't, for over a week the only think I could smell was the PR curing...! I then, resized the casted blanks and decide to make another batch and see what would happen. Not a lot of difference from the first pouring experience really, so I decided that, for whatever the reason, I was getting a much worse reaction to this stuff, then I would ever expect. It should be mention that, in my early working career, I had 2 chemical intoxication from chemical vapors inhalation (a certain type of spraying sanding sealer, and rolled floor wood varnish!)

Contacted various members already casting, offering the exclusivity of my woods supply for their castings, as I didn't wanted to create a business "clash" among our friends casting members. One of those contacted did accept trying them, so I automatically rejected any other offer to supply these woods to anyone else!

I actually thought in selling all the casting gear after I finished with the resin I had, and was no shortage of interest particularly with the 12 molds and the wood tray to separate the molds inside the pressure pot, so I was satisfied that I would get some of my money invested in this operation as I had someone buying my woods for casting, I was happy that I didn't need to do them myself.

The attempt to have my woods used by this casting friend, didn't really work as we both expected so, was obvious that it would be a long time if ever before this friend would run out of the 20kg of timbers supplied, and in a conversation we both had, this was obvious. I was suggested for to sell them to anyone (another major casting member) that wanted to use it, was no need to keep the "exclusivity", which I accepted as reasonable.

In conversation with someone living in this town, I was told of a fellow that did work in a fibro-glass factory, the factory closed some time ago and this fellow lost his job so, I went and saw him. Was evident this fellow (John) wasn't a very healthy person, his face was as dry as a bone and he looked 20 year older than what he was (47). After a short conversation he accepted to do all my castings at his place, I would supply everything and give him an idea what I wanted to have done.

Once again I was satisfied that I had someone doing this for me, someone that spend 25 years working with these type products. Once a week I would visit him and get what was done at least one week prior as I found that the first few days of the blanks coming out of the pot, the smell is a lot stronger.

He made me about 200 blanks and a few weeks ago is just passed away with a massive heart attack...!:frown: poor John!

Got all my gear back, paid what was owed to the wife (no kids) and went home a bit distressed with all this. Recently I decided to get myself a good chemical mask (double crystal filters) and start to do them myself as the wood was start pilling up a lot more than I wanted. The mask does seem to do a good job (expensive but efficient), and the sensitivity to the lightest of the PR smells, seems also to be improving.

A few days ago I decided to make new molds to make things a bit easier and faster, using a lot less resin (wasting less), and increase the run (pot capacity) of blanks done, from 12 to 21 (blanks @ 21mm square x 130mm long). I wanted to show everyone that wants to do casting or are already playing with it that, these newer molds will make the casting per blank more economical.

I will start to list here and on eBay very soon of my casted blanks, and with all due respect to all that invented the names for the casted blanks and sells them, well know here and elsewhere, I don't particularly like the name of "worthless" (sorry Curtis!) as I don't like to call "left overs" to the off-cuts I get from initial cuttings either, so my casted blanks, regardless if they are 1%, 50% or 99% resin/wood, will be called, "RESIFILL" blanks, and will be supplied with the four square corner cut out!:wink::biggrin: Not to mention that most of the woods used are not found in any other casted blank anywhere in the world, and anyone that wants to cast and don't have the wood blanks, I will sell you as much as you want/can afford and sent anywhere...!

I would gladly stop casting myself, but unless I sell this type of woods, regularly and in reasonable amounts, I will be casting more and more to catch up with the volume of suitable timber I got stored. There is obviously the extra expense of all the colours other materials and accessories, like plenty of acetone, and off-course the main ingredient the PR resin with catalizer. A 1 gallon of resin just doesn't last long but I get a fair number of blanks done!

My intention with this extra work I'm doing now is to firstly, recover whatever the blank sale price I would sell if was not "flawed" in some way, secondly recover the expense involved with all the casting products by calculating on average on many blanks I make out of a gallon of resin, adding and equal amount for all the colours, filling/effect powders, acetone, demolding agents, containers, mixers, gloves, etc., etc., etc., $1 each for labor, 10ct each for electricity and 10ct each for equipment investment. This has come to a grand total of $...!, well...that will be reveled the day I put the first groups on sale at proper forum location. The only variation in prices are the different costs for the few timber species that are a little more expensive than my normal $1 per blank. The price per blank itself will be the same if sold as a full wood pen blank, PLUS the casting costs already determine by constant testing, explained above!

Don't worry, my Resifill blanks will be "surprisingly" economical...! promise.:wink:

Update completed.

Now here they are, a "few"

Cheers

George

Attachments

-

timber preparation 001_(1).jpg33.3 KB · Views: 355

timber preparation 001_(1).jpg33.3 KB · Views: 355 -

timber preparation 005_(1).jpg46.2 KB · Views: 356

timber preparation 005_(1).jpg46.2 KB · Views: 356 -

timber preparation 006_(1).jpg41.8 KB · Views: 354

timber preparation 006_(1).jpg41.8 KB · Views: 354 -

timber preparation 007_(1).jpg46.8 KB · Views: 354

timber preparation 007_(1).jpg46.8 KB · Views: 354 -

timber preparation 002_(1).jpg27 KB · Views: 383

timber preparation 002_(1).jpg27 KB · Views: 383 -

timber preparation 1641_(1).jpg56.2 KB · Views: 418

timber preparation 1641_(1).jpg56.2 KB · Views: 418 -

timber preparation 1295_(1).jpg57.6 KB · Views: 381

timber preparation 1295_(1).jpg57.6 KB · Views: 381 -

timber preparation 1292_(1).jpg54.4 KB · Views: 401

timber preparation 1292_(1).jpg54.4 KB · Views: 401 -

timber preparation 1290_(1).jpg50.5 KB · Views: 520

timber preparation 1290_(1).jpg50.5 KB · Views: 520 -

timber preparation 008_(1).jpg49.2 KB · Views: 347

timber preparation 008_(1).jpg49.2 KB · Views: 347 -

timber preparation 1645_(1).jpg41 KB · Views: 369

timber preparation 1645_(1).jpg41 KB · Views: 369 -

timber preparation 1651_(1).jpg43.3 KB · Views: 295

timber preparation 1651_(1).jpg43.3 KB · Views: 295 -

timber preparation 1652_(1).jpg33.9 KB · Views: 285

timber preparation 1652_(1).jpg33.9 KB · Views: 285 -

timber preparation 1653_(1).jpg33.9 KB · Views: 289

timber preparation 1653_(1).jpg33.9 KB · Views: 289 -

timber preparation 1655_(1).jpg46.6 KB · Views: 379

timber preparation 1655_(1).jpg46.6 KB · Views: 379 -

timber preparation 1657_(1).jpg66.7 KB · Views: 372

timber preparation 1657_(1).jpg66.7 KB · Views: 372 -

timber preparation 1659_(1).jpg55.7 KB · Views: 391

timber preparation 1659_(1).jpg55.7 KB · Views: 391

Last edited: