I'm trying to install the VS upgrade on my Rikon 70-100 and in order to get the new motor mounted I have to disassemble some things on the old motor and I can't get the pully off the motor shaft. I got the set screw out ok but that pully will just not budge. The design doesn't allow me to use a bearing puller and after an hour of trying everything I can think of it still won't budge....Any ideas.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Can't remove pully

- Thread starter Smitty37

- Start date

Signed-In Members Don't See This Ad

Signed-In Members Don't See This Ad

monophoto

Member

Possibly a dumb question, but are there two grub screws?

I'm trying to install the VS upgrade on my Rikon 70-100 and in order to get the new motor mounted I have to disassemble some things on the old motor and I can't get the pully off the motor shaft. I got the set screw out ok but that pully will just not budge. The design doesn't allow me to use a bearing puller and after an hour of trying everything I can think of it still won't budge....Any ideas.

You mean you can't get a puller into the space?

Is the pulley aluminum? If so, maybe a little heat on the hub would help.

There's a penetrating oil called Kroil that can do amazing things at loosening frozen parts, particularly if it is caused by corrosion.

Heat would be my first try, though, since there is no telling whether someone used Loctite or something to install it. Heat will also expand the aluminum or zinc alloy of the pulley more than the steel shaft.

If that doesn't work make a sort of puller substitute by using some metal bars to suspend the whole thing in the air from the backside of the pulley and gently tap on the shaft using a brass hammer of brass drift. (assuming there is enough clearance to do that). Put something soft under it to catch it if it should suddenly pop free.

Heat would be my first try, though, since there is no telling whether someone used Loctite or something to install it. Heat will also expand the aluminum or zinc alloy of the pulley more than the steel shaft.

If that doesn't work make a sort of puller substitute by using some metal bars to suspend the whole thing in the air from the backside of the pulley and gently tap on the shaft using a brass hammer of brass drift. (assuming there is enough clearance to do that). Put something soft under it to catch it if it should suddenly pop free.

Dale Allen

Member

I found this comment and have seen other references to using heat.

"The hardest part was getting the old pully off to retrieve the motor bracket. I had to heat mine up with a torch and made a wedge out of a piece of 2X4 and it finnaly came loose."

"The hardest part was getting the old pully off to retrieve the motor bracket. I had to heat mine up with a torch and made a wedge out of a piece of 2X4 and it finnaly came loose."

NittanyLion

Member

No, just 1Possibly a dumb question, but are there two grub screws?

The pully has to be removed to get the mounting plate off. They don't come off together. I need the mounting plate for the DC motor that goes with the VS Kit.Did you pull the plate as well? See pic:

Old Codger

Member

I know this may sound stupid...but did you think of contacting Rikon and asking them for suggestions??? I've had a Rikon 1216VS for over a year and love it, and Rikon has been extremely good about any problems I've had (few!!!)...plus if Rikon didn't mfg the upgrade to VS, the mfg SHOULD offer advice on how to complete the installation... If not, I might look elsewhere!!! Good luck and safe turning to you!

The pully is caping over the shaft so a puller has nothing to pull againstI'm trying to install the VS upgrade on my Rikon 70-100 and in order to get the new motor mounted I have to disassemble some things on the old motor and I can't get the pully off the motor shaft. I got the set screw out ok but that pully will just not budge. The design doesn't allow me to use a bearing puller and after an hour of trying everything I can think of it still won't budge....Any ideas.

You mean you can't get a puller into the space?

Is the pulley aluminum? If so, maybe a little heat on the hub would help.

I'll try heat I guess...but I can call them tomorrow and see what they recommend about that. I hope I don't run into the same problem on the spindle pully.

BayouPenturner

Member

Smitty can you let us look at some pictures of the issues

I can't contact Rikon until tomorrow. So far they have been good - the pulleys with the VS were both chipped and they got me replacements in 2 days...shipped the same day I called them.I know this may sound stupid...but did you think of contacting Rikon and asking them for suggestions??? I've had a Rikon 1216VS for over a year and love it, and Rikon has been extremely good about any problems I've had (few!!!)...plus if Rikon didn't mfg the upgrade to VS, the mfg SHOULD offer advice on how to complete the installation... If not, I might look elsewhere!!! Good luck and safe turning to you!

Look at post 6 Earl, it looks exactly like that and the pulley won't budge.Smitty can you let us look at some pictures of the issues

NittanyLion

Member

Power up the motor, but make sure you have it up against a block of wood. It should spin off.

BayouPenturner

Member

sorry I did not notice the pictures. I have done things similar to that and wedged two wedges one on each side. the pulley may not budge quickly but over some time it may beak loose. good luck

The pully is caping over the shaft so a puller has nothing to pull againstI'm trying to install the VS upgrade on my Rikon 70-100 and in order to get the new motor mounted I have to disassemble some things on the old motor and I can't get the pully off the motor shaft. I got the set screw out ok but that pully will just not budge. The design doesn't allow me to use a bearing puller and after an hour of trying everything I can think of it still won't budge....Any ideas.

You mean you can't get a puller into the space?

Is the pulley aluminum? If so, maybe a little heat on the hub would help.

I'll try heat I guess...but I can call them tomorrow and see what they recommend about that. I hope I don't run into the same problem on the spindle pully.

That complicates things a bit. (if you mean the end is closed).

If the back plate is sturdy enough you might try wedging it off with two tie rod or ball joint separators, one on each side to keep the pressure even, maybe while heating it at the same time (I'd recommend trying a heat gun instead a torch if you have one).

While trying wedging the shaft will move in and out a little but the pulley won't move.The pully is caping over the shaft so a puller has nothing to pull againstI'm trying to install the VS upgrade on my Rikon 70-100 and in order to get the new motor mounted I have to disassemble some things on the old motor and I can't get the pully off the motor shaft. I got the set screw out ok but that pully will just not budge. The design doesn't allow me to use a bearing puller and after an hour of trying everything I can think of it still won't budge....Any ideas.

You mean you can't get a puller into the space?

Is the pulley aluminum? If so, maybe a little heat on the hub would help.

I'll try heat I guess...but I can call them tomorrow and see what they recommend about that. I hope I don't run into the same problem on the spindle pully.

That complicates things a bit. (if you mean the end is closed).

If the back plate is sturdy enough you might try wedging it off with two tie rod or ball joint separators, one on each side to keep the pressure even, maybe while heating it at the same time (I'd recommend trying a heat gun instead a torch if you have one).

Dale Allen

Member

Any chance you could drill a hole in the capped end large enough for the puller?

While trying wedging the shaft will move in and out a little but the pulley won't move.The pully is caping over the shaft so a puller has nothing to pull againstI'm trying to install the VS upgrade on my Rikon 70-100 and in order to get the new motor mounted I have to disassemble some things on the old motor and I can't get the pully off the motor shaft. I got the set screw out ok but that pully will just not budge. The design doesn't allow me to use a bearing puller and after an hour of trying everything I can think of it still won't budge....Any ideas.

You mean you can't get a puller into the space?

Is the pulley aluminum? If so, maybe a little heat on the hub would help.

I'll try heat I guess...but I can call them tomorrow and see what they recommend about that. I hope I don't run into the same problem on the spindle pully.

That complicates things a bit. (if you mean the end is closed).

If the back plate is sturdy enough you might try wedging it off with two tie rod or ball joint separators, one on each side to keep the pressure even, maybe while heating it at the same time (I'd recommend trying a heat gun instead a torch if you have one).

In that case I think Dale Allen may have the best approach.

It wouldn't have to be the full size of the shaft, just large enough to put a rod through it and push against the end of the shaft. That hols would also allow penetrating oil to be applied in a more effective manner than just through the setscrew hole and the small exposure at the rear of the pulley.

Any idea how far the motor shaft extends into the pulley and how deep an end bore (drilled hole) would have to be?

Curly

Member

You might also drill a hole in the end of the pulley and thread it with a tap. Put a bolt in the threaded hole and when it is tightened it will push on the end of the shaft and pull the pulley off.

A second thought, do you need to preserve the current pulley?

If not just start hacksawing it off till you get to the shaft and use the gear puller on the remaining part (or just use a dremmel or small grinder on it and carefully cut a slot through it to the shaft and use a chisel to wedge it open).

If not just start hacksawing it off till you get to the shaft and use the gear puller on the remaining part (or just use a dremmel or small grinder on it and carefully cut a slot through it to the shaft and use a chisel to wedge it open).

walshjp17

Member

I wish I could remember what I did 2 1/2 years ago when I did mine, but I do know I had no problems pulling and replacing the pulleys and motor. Calling Rikon in the morning seems to be the best next step.

BayouPenturner

Member

Smitty, have you tried wedging something between the lathe frame and the end of the pulley to move it slightly towards the motor, once it move either direction it should begin to free up. That way if it frozen due to corrosion between the alloy pulley and steel shaft you can possibly break it loose which should let penetrating oil get in the pulley to free it up.

PenMan1

Member

I know this sounds crazy, but it only takes a second to check it out.

I removed the grub screw from a pulley shaft once, then beat, banged, heated and wiggled the pulley for hours-all to no avail.

THEN, UPON CLOSER INSPECTION, I found a Woodruff Key on the shaft. After simply tapping back the key, the pulley slide right off.

It might be worth pulling out the magnifying mirror to make a 10 second inspection of the pulley's center.

I removed the grub screw from a pulley shaft once, then beat, banged, heated and wiggled the pulley for hours-all to no avail.

THEN, UPON CLOSER INSPECTION, I found a Woodruff Key on the shaft. After simply tapping back the key, the pulley slide right off.

It might be worth pulling out the magnifying mirror to make a 10 second inspection of the pulley's center.

edstreet

Member

Epic face palm!

Lets do things that will damage the new lathe. Yea that's always a good choice, *NOT*.

Try RTFM?

Things are 'stuck' for a reason. Once you find that reason all will become clear at that point. There is no sense in forcing things.

Lets do things that will damage the new lathe. Yea that's always a good choice, *NOT*.

Try RTFM?

- Remove spring loaded motor locking handle.

- Uninstall the belt from the lathe.

- Loosen the nylon lock nut (A-FIG.4) using a 13MM wrench then remove motor.

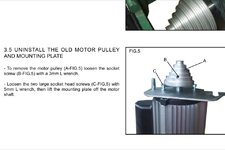

- To remove the motor pulley (A-FIG.5) loosen the socket screw (B-FIG.5) with a 3mm L wrench.

- Loosen the two large socket head screws (C-FIG.5) with 5mm L wrench, then lift the mounting plate off the motor shaft.

Things are 'stuck' for a reason. Once you find that reason all will become clear at that point. There is no sense in forcing things.

Last edited:

PenMan1

Member

I'm assuming that you WERE able to complete instruction step 3.4 and remove the motor and pulley from the lathe?

PenMan1

Member

This is just the redneck in me popping right out. BUT figure 5 in step 3.5 of the instructions show the two screws holding the mounting plate in place ARE LOOSENED. Additionally, in the drawing, those two screws appear to line up on the edges of the pulley.

IF (BIG WORD, here) this IS in fact the case, by loosening those two screws as far as possible, SHOULD (another BIG word) allow you to lightly tap the back of the mounting bracket thus forcing those to screw heads to lift the pulley off the shaft.

IF (BIG WORD, here) this IS in fact the case, by loosening those two screws as far as possible, SHOULD (another BIG word) allow you to lightly tap the back of the mounting bracket thus forcing those to screw heads to lift the pulley off the shaft.

PenMan1

Member

So far, the reviews I've found of this kit and it's installation say getting this pulley off requires heat/torque.

This link may be helpful.

Hktvx Jmo Foptv Cdgz: Rikon 79-100VS Mini Lathe Variable Speed Kit

This link may be helpful.

Hktvx Jmo Foptv Cdgz: Rikon 79-100VS Mini Lathe Variable Speed Kit

jimjam66

Member

Sorry, I know this doesn't help with your problem but the thread title reminded me of the surgeon's post-op report: "There's bad news and good news, ma'am. We weren't able to remove it but we did manage to change the batteries!"

Sorry - I'll get my hat and coat ...

Sorry - I'll get my hat and coat ...

I drilled the end of the pulley and used a gear/bearing puller and got it off.

I't will still be useable too which surprised me.

I't will still be useable too which surprised me.

Since you've done this maybe you can help.I wish I could remember what I did 2 1/2 years ago when I did mine, but I do know I had no problems pulling and replacing the pulleys and motor. Calling Rikon in the morning seems to be the best next step.

Looking at the new box which has the pc board mounted in it. You put the box in, pull the power and cable wires through the back of the box and hook up to the PC board. Then you have to mount the PC board to the side of the box. But the wires don't seem to be long enough to let the box come all the way out which it has to do to get the screws holding the pc board in....Do you remember what you did?

walshjp17

Member

Smitty, I'd be lying if I said I remember. I do recall however, having to fiddle with the power cord and the stupid retaining clip. I may have pulled the cord in a bit to give me more room, but that is just a vague, cloudy memory -- to much Jameson's, I guess (if there is such a a thing as too much Jameson's :wink .

.

SteveG

Member

Ya Got it!!! :bananen_smilies068::banana::bananen_smilies008::bananen_smilies046::bananen_smilies046::bananen_smilies026::RockOn::bananen_smilies019::bananen_smilies022::bananen_smilies022::bananen_smilies022::banana::bananen_smilies047::bananen_smilies039::bananen_smilies051::bananen_smilies068::bananen_smilies068::bananen_smilies104:

Dale Allen

Member

You might also drill a hole in the end of the pulley and thread it with a tap. Put a bolt in the threaded hole and when it is tightened it will push on the end of the shaft and pull the pulley off.

Probably not if the pulley is aluminum!

BayouPenturner

Member

glad you got the pulley off. I hope you find a fix for the other issue.

I can fix the other issue...It just annoyed me.

Dale Allen

Member

I can fix the other issue...It just annoyed me.

Hehe...you gotta admit though that it is better to be annoyed by a machine than by a person!:biggrin:

Curly

Member

You might also drill a hole in the end of the pulley and thread it with a tap. Put a bolt in the threaded hole and when it is tightened it will push on the end of the shaft and pull the pulley off.

Probably not if the pulley is aluminum!

Actually it will work if there is enough material to take the thread. if it is an eighth of an inch then no, if half an inch of metal then likely easily. Even if it did fail it would most likely only strip the threads out leaving a hole that could be opened up to a larger size. It is worth a try before beating and putting torches to it if there is no room for a puller.

Last edited:

The pully is off ---- I drilled a hole in the motor shaft cap on the pulley and used bearing pullers to remove it. The shaft of the moto looks a little battered and I know that I didn't do it so part of my problem was in the motor shaft itself.You might also drill a hole in the end of the pulley and thread it with a tap. Put a bolt in the threaded hole and when it is tightened it will push on the end of the shaft and pull the pulley off.

Probably not if the pulley is aluminum!

Actually it will work if there is enough material to take the thread. if it is an eighth of an inch then no, if half an inch of metal then likely easily. Even if it did fail it would most likely only strip the threads out leaving a hole that could be opened up to a larger size. It is worth a try before beating and putting torches to it if there is no room for a puller.

Signed-In Members Don't See This Ad

All issues resolved - unit is up and running. So far - belt is a piece of cake to change so there will be no problems moving from range to range. There are a couple of things that they need to work on:

They have strain reliefs for the power and motor cables that are virtually impossible to get back on once you have removed them, at least they looked and felt that way to me, my guess is the factory uses a special tool designed for installing them;

There are two instructions in the on line manual that are wrong but common sense gets you past that;

They omitted one important instruction altogether but it is obvious when you get there that you have to do it.

Once I got it buttoned up though it purred like a kitten.

They have strain reliefs for the power and motor cables that are virtually impossible to get back on once you have removed them, at least they looked and felt that way to me, my guess is the factory uses a special tool designed for installing them;

There are two instructions in the on line manual that are wrong but common sense gets you past that;

They omitted one important instruction altogether but it is obvious when you get there that you have to do it.

Once I got it buttoned up though it purred like a kitten.