MorganGrafixx

Member

So recently I have taken a liking to woodworking with tools that lack power cords or batteries. I built myself a rock solid work bench using mostly hand tools. The bench is made up of 3 torsion boxes held together by 2 threaded steel rods 5/8" thick. Most things I was able to do with hand tools, but there were some that I had to use power tools for because I didn't have the right hand tool for that particular job. Used handsaws, screwdrivers, hammer and chisels, etc. But I digress...

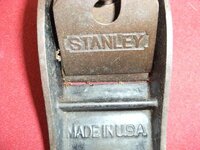

The main point of this post is to glean some info from my elders. A couple weeks ago, my wife and I spent 5 days running around the N, Georgia mountains visiting obscure antique shops and little hole in the wall eateries for our 11th anniversary. We came across one antique shop in Blue Ridge (i think) that had at least 3 of everything know to man. I stumbled on an area that was loaded with old, rusted, beaten hand tools. Well, this one bench plane caught my eye and I swear she was giving me that look...you know the look...the one you get from the lonely dog at the pound that could melt a hole through steel. So I picked her up and started going through the mental checklist of what you should look for. Missing pieces, broken this or that, dents, chips, cracks, etc. I couldn't really find anything that was bad enough to make me toss it back. The tag hanging off it said $45....I though that might be a bit more than I wanted to pay for an old plane...then I saw the "everything in this section 40% off" sign! Well, my decision was made by this point.

I decide I would try and restore it to it's former glory. I've watched just about every video I can find and gone through article after article by hand tool wizard Joe Schmoe, or plane expert What'sHisFace, but I wanted to post it to my fellow IAPers in hopes that someone has some advice on stuff to watch out for. Or simple fixes that make a big difference.

Also, if anyone out there knows the estimated value of this thing, that would be great too. After several days of researching, the closest I can come is that it is from the 1880s-1920s. Not sure how much truth there is to that, so maybe someone here can help me out with that too.

The main point of this post is to glean some info from my elders. A couple weeks ago, my wife and I spent 5 days running around the N, Georgia mountains visiting obscure antique shops and little hole in the wall eateries for our 11th anniversary. We came across one antique shop in Blue Ridge (i think) that had at least 3 of everything know to man. I stumbled on an area that was loaded with old, rusted, beaten hand tools. Well, this one bench plane caught my eye and I swear she was giving me that look...you know the look...the one you get from the lonely dog at the pound that could melt a hole through steel. So I picked her up and started going through the mental checklist of what you should look for. Missing pieces, broken this or that, dents, chips, cracks, etc. I couldn't really find anything that was bad enough to make me toss it back. The tag hanging off it said $45....I though that might be a bit more than I wanted to pay for an old plane...then I saw the "everything in this section 40% off" sign! Well, my decision was made by this point.

I decide I would try and restore it to it's former glory. I've watched just about every video I can find and gone through article after article by hand tool wizard Joe Schmoe, or plane expert What'sHisFace, but I wanted to post it to my fellow IAPers in hopes that someone has some advice on stuff to watch out for. Or simple fixes that make a big difference.

Also, if anyone out there knows the estimated value of this thing, that would be great too. After several days of researching, the closest I can come is that it is from the 1880s-1920s. Not sure how much truth there is to that, so maybe someone here can help me out with that too.