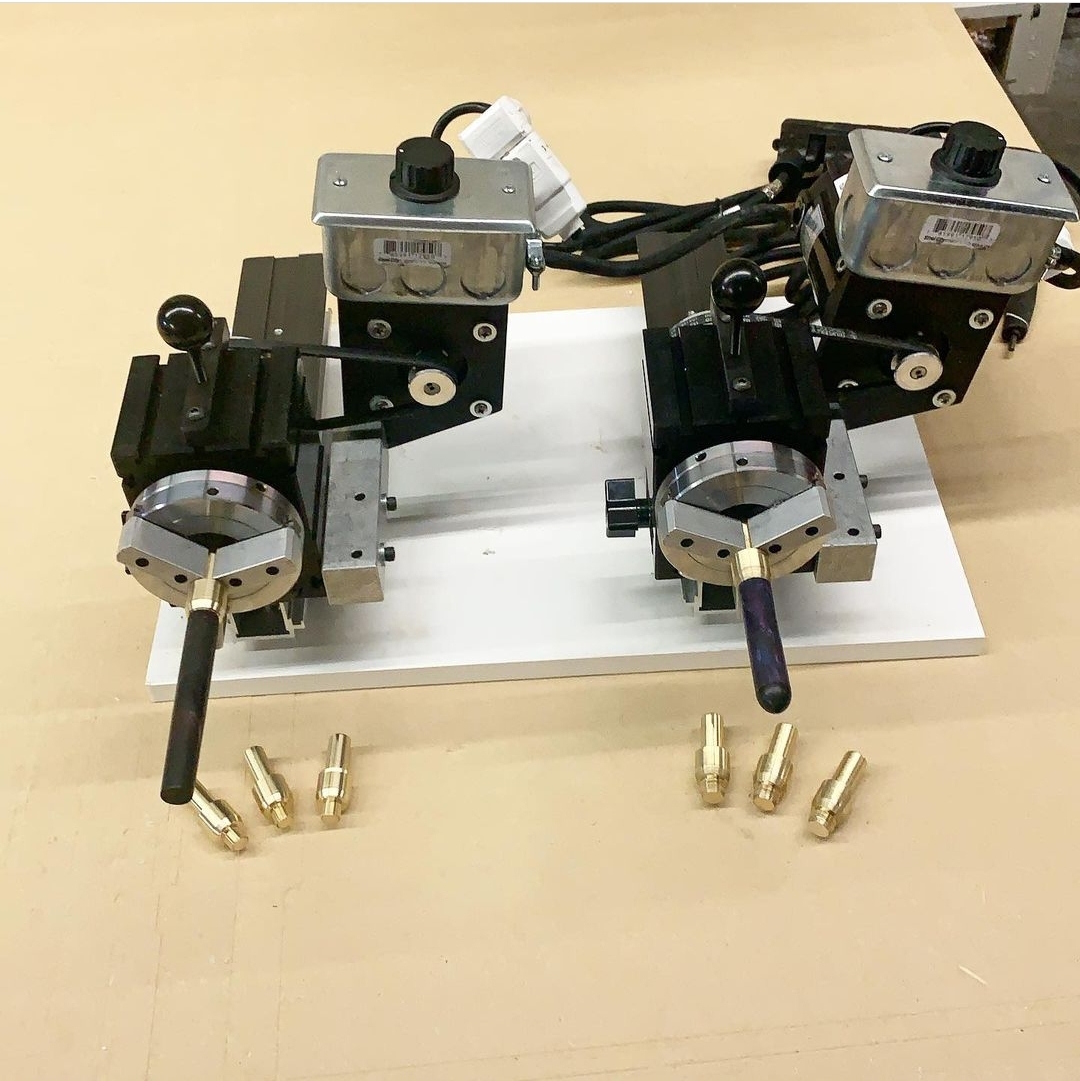

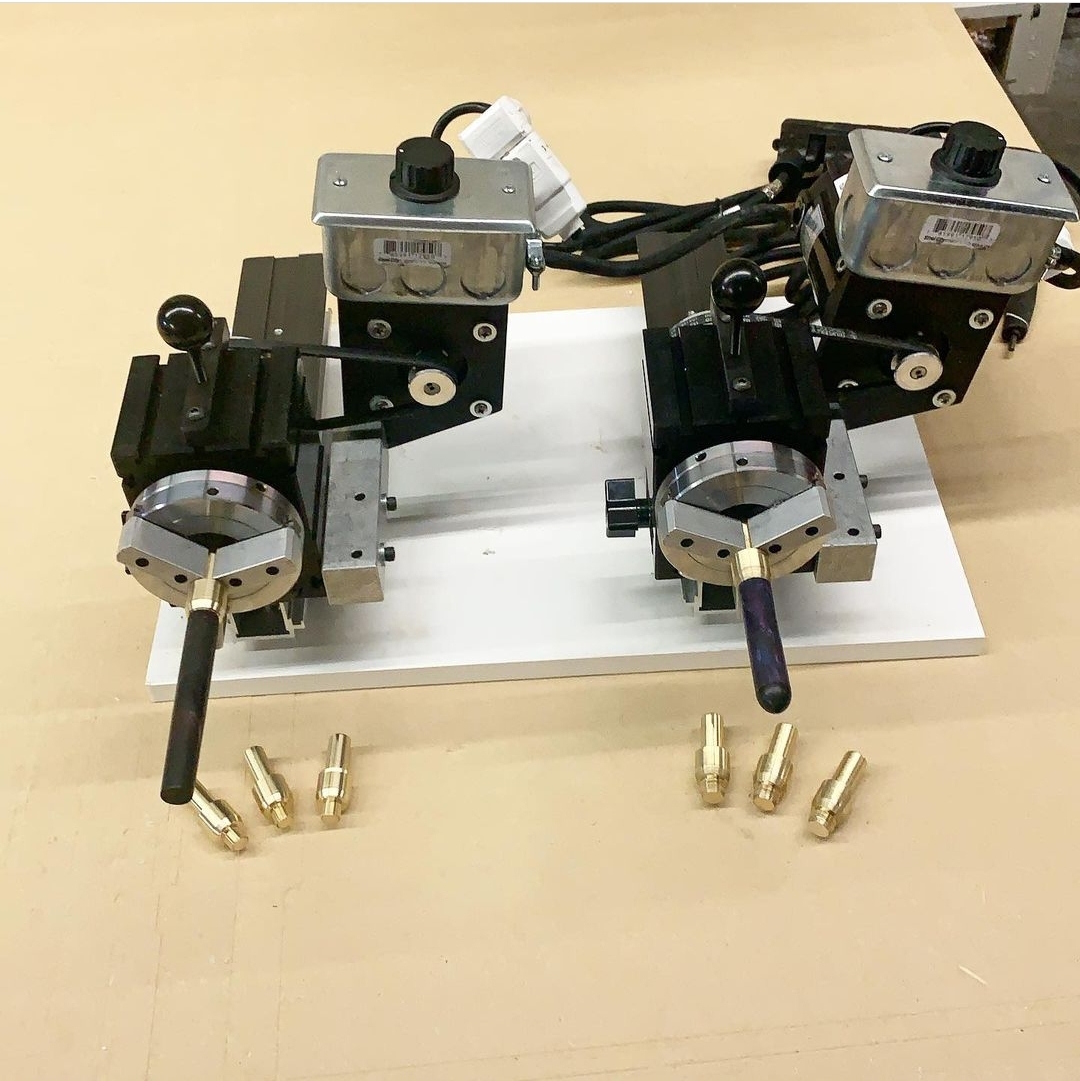

Do you have any other photos of these machines? I know they are both Taig headstocks, ways and chucks, but the motor and mounts have me baffled. They could be the same or a variation of the universal sewing machine motor I mentioned in the first post.

Unless you are set on building like machines I could come up with a cheaper solutions. A Taig headstock is $65, the bed/ways. about $70, the chuck is $72. Motor as shown now is an unknown, the speed controller about $20. Machining the fittings etc., cost is an unknown. Known is about $225. Unknown costs is a guess of another$50 to $100.

I'm looking to build sanding and polishing station similar to the one in this picture made by Sean at the London Pen Company but I haven't been able to find information on where I could get the parts to make it appreciate any help thank you

I'm looking to build sanding and polishing station similar to the one in this picture made by Sean at the London Pen Company but I haven't been able to find information on where I could get the parts to make it appreciate any help thank you