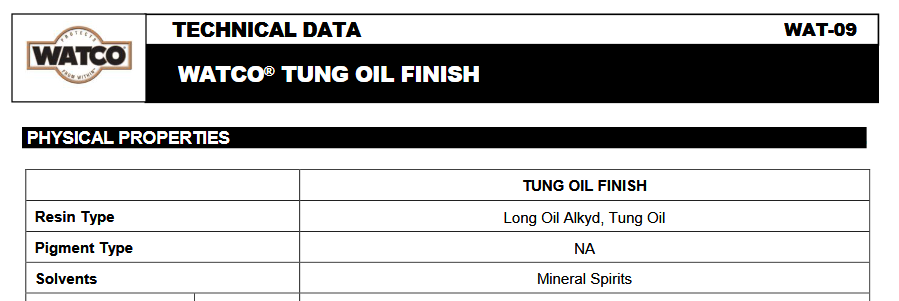

To John's point - its important to understand exactly what you are using. You mentioned Watco - I believe that Watco Tung Oil (WAT-09) is more correctly described as a 'long-oil alkyd varnish' with a Tung oil base, and the label on the can clearly says 'Tung Oil Finish".

To clarify - pure oils are just that - oils that are expressed from the seeds of plants - flax in the case of BLO, the Tung tree in the case of Tung Oil, walnuts in the case of walnut oil, etc. Those are the three most common 'drying oils' - that is, oils that will polymerize (combine with oxygen in the air) to create a plastic-like finish. Oils penetrate into the fibers of wood such that the polymerized oil finish is actually within the fibers of the wood. Both linseed oil and Tung oil polymerize naturally, although the polymerization process takes much longer with raw linseed oil. The product sold as BLO is treated with additives to make it cure faster. The main difference between linseed oil and Tung oil is that polymerized linseed oil is more amber in color than polymerized Tung oil, while polymerized Tung oil is more water resistant than polymerized linseed oil. Walnut oil is less amber than Tung oil but not as water resistant. A cured oil finish leaves the wood feeling like sanded wood, and will have very low lustre. The

truly pure version of these oils are all 'food safe', but that is not the case if metallic dryers are added to make them cure faster (as is the case with BLO). That said, some people may still have allergic reactions to the original nut or seed from which the oil was expressed.

Any of these oils can be combined with a solvent such as turpentine or mineral spirits to make a 'Danish oil'. The Watco product uses 'Stoddard Solvent' which is a less-flamable form of mineral spirits. The main advantage of Danish oils is that because they are thinned with a solvent, they penetrate better (further) into wood fibers. A cured Danish oil finish will have slightly more lustre than a pure oil finish.

When varnish solids are added to Danish oil, the result is a 'long oil varnish', or 'wiping varnish' The varnish solids can be alkyds (as in the Watco product) or polyurethane (as in Minwax WOP). While varnishes can penetrate into the wood fibers so some degree (less than with Danish oils), the main claim to fame is that they cure to form a skin over the outside of the wood. As a result, a varnish finish will be harder than a pure oil or Danish oil finish, and can take on various degrees of sheen from matt all the way to very glossy.

I keep both BLO and pure Tung oil in my shop. I make a utility finish (for tool handles etc) by thinning ordinary paste wax with turpentine, and then blending in some BLO. I make a fancy finish for bottle stoppers, bowls, and boxes by blending pure Tung oil, turpentine, and a commercial spar (Tung oil and alkyd) varnish. And I make a similar finish for items such as walking canes that require a finish that can withstand more physical abuse by combining pure Tung oil, turpentine, and a Tung-oil-based polyurethane varnish. And from time-to-time, I also use a Danish oil made from either BLO or Tung oil as a finish - for example, its easier to soak some Danish oil into an item with a captive ring than it is to try to apply a wiping varnish on that loose ring. And for pens, I make a friction polish by combining pure Tung oil, lacquer, and lacquer thinner.