sorcerertd

Member

What do you folks use to square your blanks? I've seen a few ways, but want to eliminate that dreaded wobble as much as possible. I'm not sure anything is foolproof without precision equipment, but I'm on a low budget.

I use a combination of a barrel trimmer and a home made sanding jig. View attachment 228705

I tried doing it this way, but found trying to sand the blank in the center of the sanding disc wasn't as effective. So I made an offset jig that sanded the blank to the side of center. That worked better. But I didn't like having to set up the jig every time I needed to trim blanks. It's much easier and more convenient for me to use a trimmer in the drill press.

I may be in the minority, as an old school guy. But I've used this trimmer since '06 https://www.pennstateind.com/store/PKTRIM734.html

Very budget friendly. Can be used in a hand drill or drill press. You will hear from others who have either bought or made sanding jigs, that can mount on your lathe. They are pretty cool.

I agree.I tried doing it this way, but found trying to sand the blank in the center of the sanding disc wasn't as effective. So I made an offset jig that sanded the blank to the side of center. That worked better. But I didn't like having to set up the jig every time I needed to trim blanks. It's much easier and more convenient for me to use a trimmer in the drill press.

You're supposed to make money?Holy crap, that ultra shear kit is expensive! Maybe if I start making some good money off this hobby in the future...

I do have a nice disc sander, though I'm not sure I trust the miter gauge on it.

Ha, I just want to support my habit. This turning stuff gets expensive. I'd just like it to cover most of its own expenses.You're supposed to make money?

Sign in office- This is a non-profit organization. We didn't plan on it being that.

Holy crap, that ultra shear kit is expensive! Maybe if I start making some good money off this hobby in the future...

I do have a nice disc sander, though I'm not sure I trust the miter gauge on it.

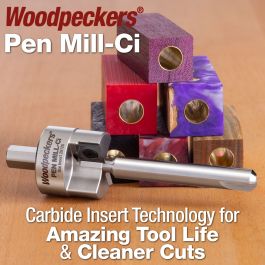

Can't justify the cost. Been using the Woodcraft pen mill for years. Touch up with a diamond file and square away.By the time you've worn out a half dozen HSS Pen mills, you'll be asking yourself why didn't I buy the replaceable carbide one originally.

Wow, that is new! It differs from the Woodpecker in that the barrels are sleeves, rather than individual pieces. Probably cuts back on the costs somewhat. The head doesn't look too much different than the Woodpecker.Hmm, this barrel trimmer is a new item for PSI. It is certainly more affordable @ $70