I am kinda bummed. It is an hour drive to a decent sized town that would have fancy stuff like Baltic Birch plywood.

I was recently in town and found myself in the market for some said plywood. Needing a piece at least 30" X 18 " to make a table saw frame miter sled, i was excited to find a 30X24. I brought it home with me, and just stacked it in my shop.

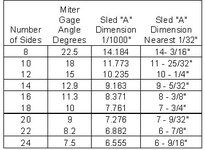

Tonight, i went back to the website with the sled building directions. It said that the 30" measurement is critical. So, out of curiosity, i grabbed a tape and measured the plywood hunk. 29 11/16" by 23 3/4". I really expected the measurements to be correct. Granted, this is the first piece of plywood i have bought from this source. I have bought hunks of solid exotics there that were always correct on the measurements. What a bummer. Now i will either have to drive an hur one way to get a different piece of wood, or try to make it work which would mean figuring out all the measurements all over.

Moral of the story... Carry a tape measure when you plan to buy pieces of plywood.

I was recently in town and found myself in the market for some said plywood. Needing a piece at least 30" X 18 " to make a table saw frame miter sled, i was excited to find a 30X24. I brought it home with me, and just stacked it in my shop.

Tonight, i went back to the website with the sled building directions. It said that the 30" measurement is critical. So, out of curiosity, i grabbed a tape and measured the plywood hunk. 29 11/16" by 23 3/4". I really expected the measurements to be correct. Granted, this is the first piece of plywood i have bought from this source. I have bought hunks of solid exotics there that were always correct on the measurements. What a bummer. Now i will either have to drive an hur one way to get a different piece of wood, or try to make it work which would mean figuring out all the measurements all over.

Moral of the story... Carry a tape measure when you plan to buy pieces of plywood.