Here's an alternative to buying hard to find drill bits. It's called a Boring Head. They are used primarily in milling machines but are quite at home in a lathe tailstock too.

First you'd drill a hole smaller than what you need, then mount the boring head and adjust the bit so that it just skims the inside of the hole you drilled. Make a note of the setting on the dial and measure the diameter of the skimmed hole. Now just adjust the bit with the dial graduations till your kit tube fits perfectly.

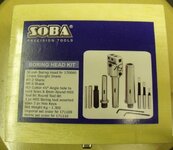

This set is is nice because it came with various accessories.

I'll check the UK price from where I got this one, but I'm positive that you guys can get them cheaper. Possibly for the same price as 2 or 3 big drill bits.:wink:

Just checked...£70 incl tax and UK delivery. http://www.chronos.ltd.uk/acatalog/Chronos_Catalogue_Boring_Heads_89.html

Little Machine Shop has them for much cheaper...http://littlemachineshop.com/products/product_search.php?critFast=boring+head&B1=Product+Search Just pick and choose the head, morse taper and bit you want.

First you'd drill a hole smaller than what you need, then mount the boring head and adjust the bit so that it just skims the inside of the hole you drilled. Make a note of the setting on the dial and measure the diameter of the skimmed hole. Now just adjust the bit with the dial graduations till your kit tube fits perfectly.

This set is is nice because it came with various accessories.

I'll check the UK price from where I got this one, but I'm positive that you guys can get them cheaper. Possibly for the same price as 2 or 3 big drill bits.:wink:

Just checked...£70 incl tax and UK delivery. http://www.chronos.ltd.uk/acatalog/Chronos_Catalogue_Boring_Heads_89.html

Little Machine Shop has them for much cheaper...http://littlemachineshop.com/products/product_search.php?critFast=boring+head&B1=Product+Search Just pick and choose the head, morse taper and bit you want.

Attachments

Last edited: