If you are looking at doing segmented pens...I think the bandsaw would work. I bought a bandsaw...well, for many reasons, and to make many things, but one of them was to do segmenting. I spent some time watching youtube videos of people creating segmented pens. All but one used a bandsaw, the other used one of those small table saws like you had.

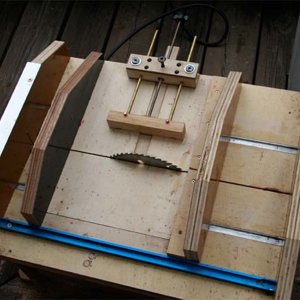

Most of the videos I was watching showed people using home made little bandsaw sleds with angle tools so they could cut at consistent angles with consistent support of the blanks. So, I built a sled of my own, for the same reason. A lot of people use a router to cut channels for things like T-track and miter track, but I chose a different route. I used two layers of wood, and just cut the top layer strait so I could separate the wood to make T-track and miter track channels. I then bolted it all together. Was pretty strait forward. It has some configurable options...one is a solid block of wood that runs across the sled perpendicular to the blade for easy strait cuts (just to do my normal blank cutting). I can take that off, and use the miter track with a miter guide with a T-track fence in it for angled cuts for segmenting.

One thing I haven't done yet is figure out how to do cuts with the blade angled. The bandsaw I have supports angling of the table...but, I'm still a bit new with the bandsaw in general, and haven't gotten to the stage of trying to adjust the table. So most of the segmenting I do is just to support say angled bands of metal and the like, hopefully soon celtic knots and half knots.