You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A couple of Aluminium pens

- Thread starter BradG

- Start date

Signed-In Members Don't See This Ad

See more from BradG

With a secret perspex splash screen which hides in a cupboard

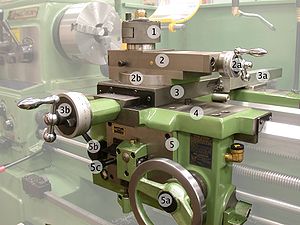

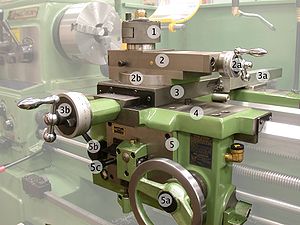

Rusty, as you know on a woodlathe you have a tool rest and use various hand tools.

Engineer Lathes have a tool holder which are adjusted by the thou, which moves on a carriage. you will find it alot easier to cut curves etc with a wood lathe for pen turning, but never the less it can be done on a metal lathe. All of the pens on the original post have been done on a metal lathe

Wiki article here on metal lathes

http://en.wikipedia.org/wiki/Lathe_(metal)

Signed-In Members Don't See This Ad

vallealbert

Member

Elegant pens....well done...

Super Dave

Member

Nice lookinf pen. You don't have to worry about it slipping out of your hand.

Dave

Dave

BradG

Member

Indeed! the knurling certainly does give a good grip

Jgrden

Member

Hey, howdja do that?? Knurling??? The gold bands ??

BradG

Member

Hi John

The gold parts are from the pen kit itself. a knurling tool is used on an engineers lathe to cut diamond or other patterns into metal for either decoration or to aid grip.

Most of my machinery is geared up toward metal oppose to wood.

The gold parts are from the pen kit itself. a knurling tool is used on an engineers lathe to cut diamond or other patterns into metal for either decoration or to aid grip.

Most of my machinery is geared up toward metal oppose to wood.

How the heck do you work in such a clean shop?

Ruby pen turning

Member

Very nice work but now I want my bedroom back.

BradG

Member

with a strict cleaning regime every time i leave the shop hunter! lol

Indeed Ruby, everyone needs their own room!

and just for a bit of overkill!:

a 10 Tonne hydraulic press which i use for the heavier jobs, and even to the lighter jobs like assembling pens! (just got to be careful not to pancake the pen

Indeed Ruby, everyone needs their own room!

and just for a bit of overkill!:

a 10 Tonne hydraulic press which i use for the heavier jobs, and even to the lighter jobs like assembling pens! (just got to be careful not to pancake the pen

Last edited:

IPD_Mr

Member

Very nicely done. I am with Hunter, how the heck do you keep the art work so clean with a metal lathe sitting directly under it. That is un-real.

RustySplinters

Member

So what differs in a metal lathe versus a wood lathe? All of these aluminum pends and the different things that Jeff has made has made me want to be able to turn metal.

Same for the tools! How do metal turning tools differ from wood?

Same for the tools! How do metal turning tools differ from wood?

BradG

Member

Very nicely done. I am with Hunter, how the heck do you keep the art work so clean with a metal lathe sitting directly under it. That is un-real.

With a secret perspex splash screen which hides in a cupboard

Rusty, as you know on a woodlathe you have a tool rest and use various hand tools.

Engineer Lathes have a tool holder which are adjusted by the thou, which moves on a carriage. you will find it alot easier to cut curves etc with a wood lathe for pen turning, but never the less it can be done on a metal lathe. All of the pens on the original post have been done on a metal lathe

Wiki article here on metal lathes

http://en.wikipedia.org/wiki/Lathe_(metal)

Last edited:

BradG

Member

Just taken delivery of my sulphuric acid so i can start anodising! well... as soon as the dye arrives. Very pleased!

txbatons

Member

That does it, I will never EVER post a photo of my work shop!

Jgrden

Member

:glasses-cool:That is what I need, a knurling tool. :glasses-cool:

minus459

Member

That does it I need to marry BradG to keep my shed clean

Rounder

Member

FIRE!!! FIRE!!! YOUR SHOP IS ON FIRE!!!

Now that is an orange room. I would have to wear sunglasses in there to work. Very, very nice looking shop though. Can I come over and help you mess it up, LOL?:wink: That just ain't right.

Now that is an orange room. I would have to wear sunglasses in there to work. Very, very nice looking shop though. Can I come over and help you mess it up, LOL?:wink: That just ain't right.

BradG

Member

Rounder, Well it sure as hell stops me falling asleep in there  and sure you can help me mess it up, you can also help scrub it down afterwards :biggrin:

and sure you can help me mess it up, you can also help scrub it down afterwards :biggrin:

Already married Minus, although im sure she wishes i would apply the same logic to the rest of the house

txbatons if it makes you feel any better its not always spotless!

jgrden, a great tool to use.. i have never tried it with a hardwood... that may be a good experiment. have done with softwood... but needless to say it came out a bit mushed

Already married Minus, although im sure she wishes i would apply the same logic to the rest of the house

txbatons if it makes you feel any better its not always spotless!

jgrden, a great tool to use.. i have never tried it with a hardwood... that may be a good experiment. have done with softwood... but needless to say it came out a bit mushed

Jeff G

Member

wow those are beauties! I just picked up an old..older than me! craftsman 618 lathe yesterday and i look forward to making some pens like those and a lot of other new things.

mind if i ask ya a question or three in the near future?

I plan on stripping my new machine down and rebuilding it s it will be a lil while before i get down to making a pen on it though..

Peace all

jeff G

mind if i ask ya a question or three in the near future?

I plan on stripping my new machine down and rebuilding it s it will be a lil while before i get down to making a pen on it though..

Peace all

jeff G

BradG

Member

Feel free Jeff, that's what we are here for

You'l soon be addicted to your new toy

You'l soon be addicted to your new toy

achennau

Member

Rockler sells a Robert Sorby micro spiralling tool that you can do that with, with practice. I haven't tried it on aluminum yet but probably will tomorrow now that I see that. It does work real good on wood

mrojas

Member

That's not a shop, it's a surgical room! Way to go Brad! I couldn't find a thing in a shop that clean!!

djpnevans

Member

Well done mate love your pens and even better love the work shop. I am keen to see how you go with the anodizing I have given it a bit of a go with not much luck.

David

David

BradG

Member

achennau, I have come across those before. theres also a motorised jig which takes a dremmel i have sen for adding calved details to pens

mrojas, its too easy for me to loose electronic components in a messy workshop so theres my motive for keeping it clean

djpnevans, il be sure to post some more with my venture into anodising. also looking at chrome, zinc & copper plating

mrojas, its too easy for me to loose electronic components in a messy workshop so theres my motive for keeping it clean

djpnevans, il be sure to post some more with my venture into anodising. also looking at chrome, zinc & copper plating

djpnevans

Member

I will keep an eye out for it.

David

David