NGLJ

Member

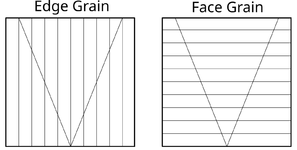

I've started making blanks from laminated staves, typically 6 and 8 staves per blank. The woods in the attached 8 stave Sierra are padauk, walnut, sapele and maple. I am also making 12 and 16 stave blanks from the off-cuts from making the 6 and 8 staves. The end pieces are walnut. The drilling angle for the twist was 17 degrees into 1¼" wide blank. I make the blank by first making a 6" semi-circular piece (4 pieces cut at a 22.5 degree angle on the bandsaw for an 8 stave blank), sanding the face flat, cutting it into 2 pieces and gluing the 2 pieces together to make a 3" finished blank. Then I turn the blank round on the lathe before drilling. Any slight out of symmetry in the round blank is eliminated during turning. I cut the staves from ¾" x ¾" x 6" laminations. There are 2 different ways to orient the laminations for cutting, one with the face grain facing up and one with the edge grain facing up, each giving a different result. My work so far is with the edge grain facing up, which I think gives a more pleasing result. I plan to the try the face grain option at some point.