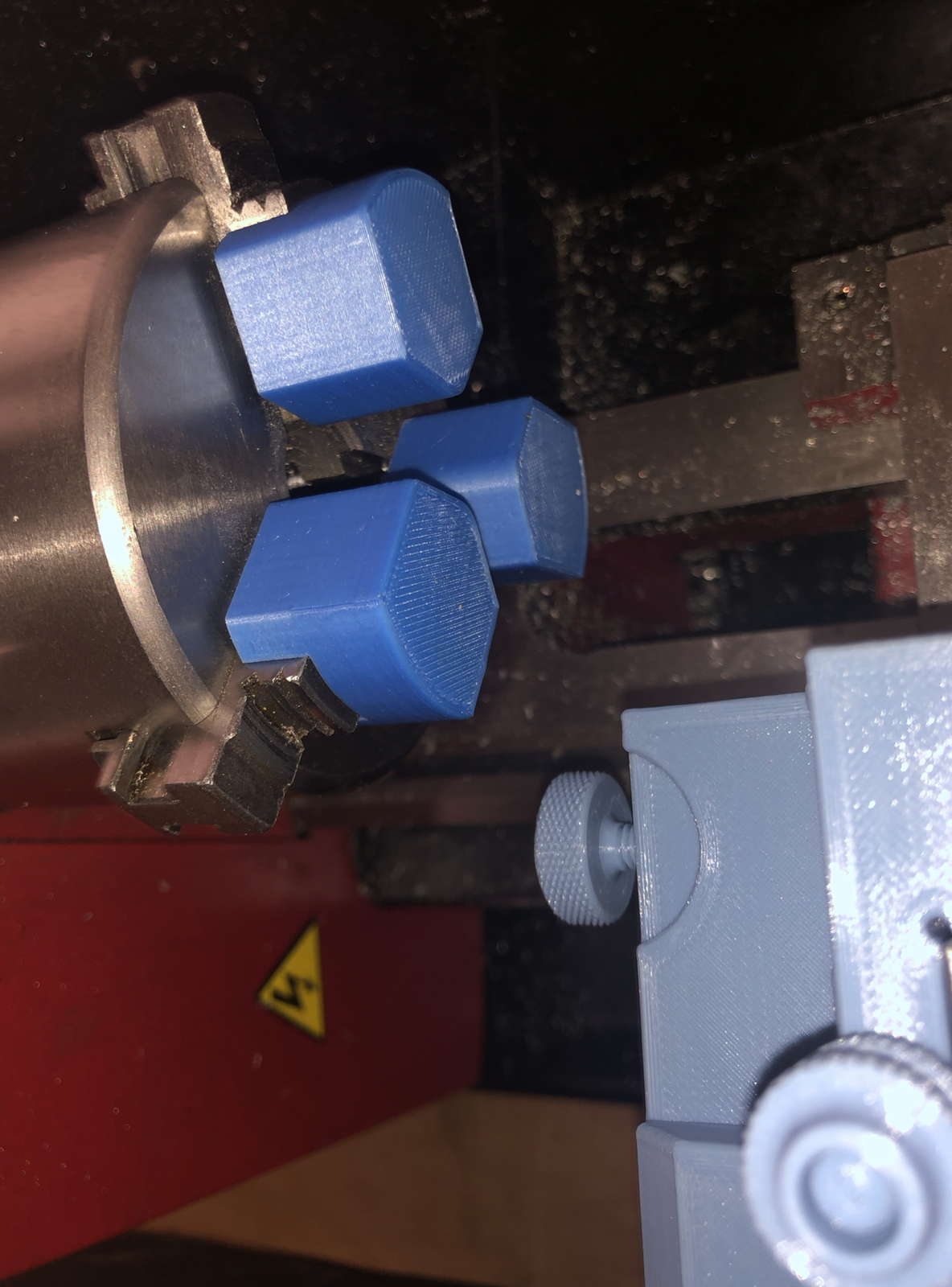

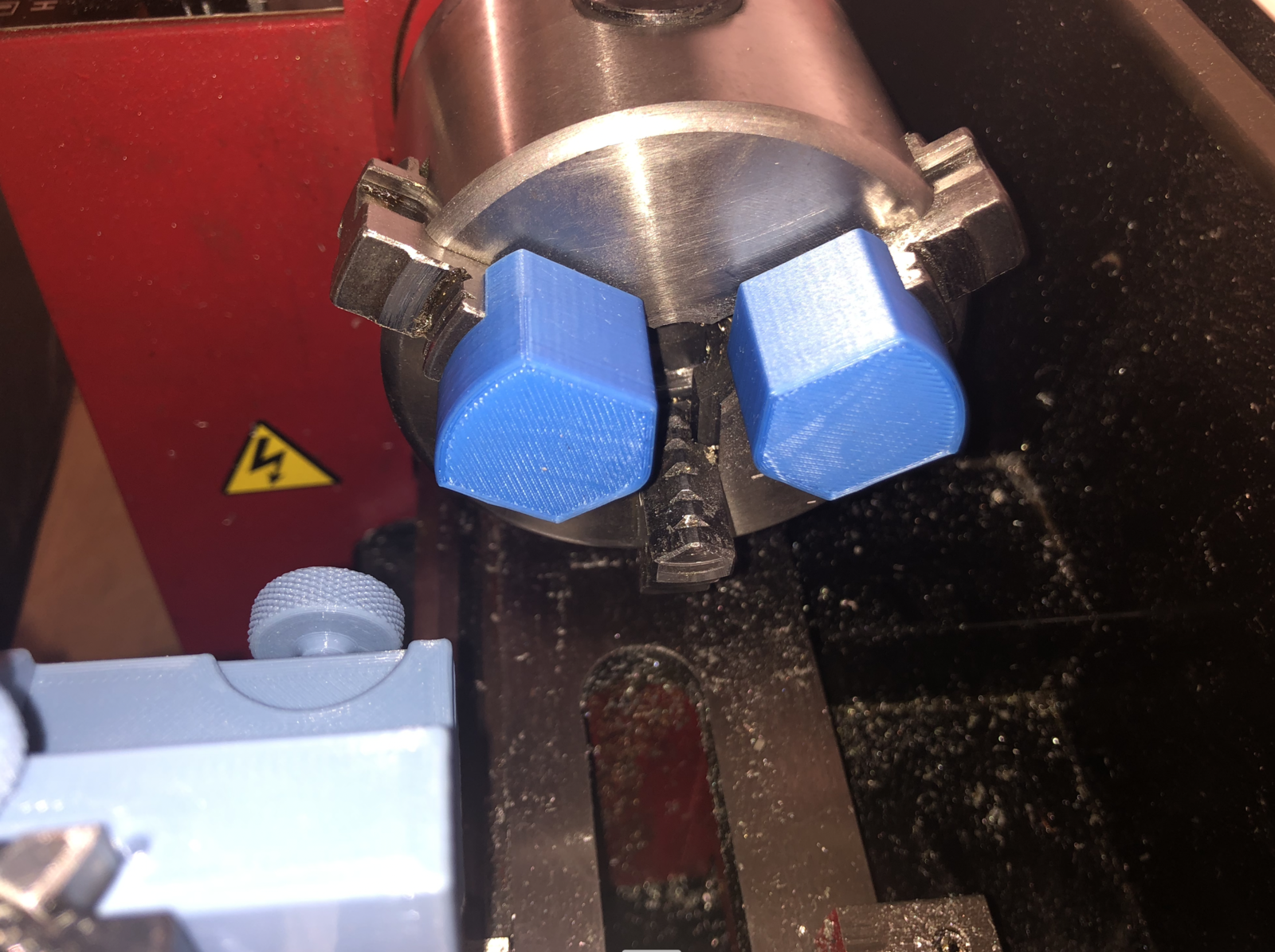

Would these be for preventing marking the object being held?

In machining "soft jaws" are meant for holding awkward parts or to ensure concentricity. They are trued up in the lathe so there is no runout or shaped to grip parts being turned. They are usually aluminium or soft steel hence the name rather than hardened jaws for wear resistance the chucks come with.

I would suggest you lightly cut the inside face with a boring bar to ensure perfect concentricity. It will ensure everything is perfectly aligned when flipping end for end etc.

First time I have seen printed ones.