workinforwood

Member

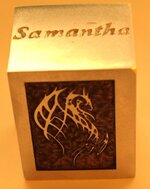

This is my first dragon being cut out, and is still cutting right now. It's 3 hrs in, about 1/2 done I think. Took me about 4 weeks to design and cost me quite a bank roll! :redface: Hey..I never ran one of these before and I had a ton of hickups along the way, mostly with programming. This dragon will be about 1.25x2" and .125 deep.

Pic 1 you see the little block of aluminum I got at a garage sale.

Pic 2, the machine moved to cut position 1

Pic 3, a zoom out of the machine as it floods away. yes..that is one heck of a vise you can sure throw out the back moving it around!

Pic 4, you can see the square pocket and outline of the dragon submerged under a bath of coolant..yes the coolant looks and smells like antifreeze and it's pretty sticky too. Eventually when the outside is all finished the machine will move into the inside of the dragon and cut more pockets.

I thought maybe my camera could do a few minutes of video, but nope, doesn't do that..all I can show is some pics of my fun. I have lots to learn, but at least I feel I made it to the base of the mountain.

Pic 1 you see the little block of aluminum I got at a garage sale.

Pic 2, the machine moved to cut position 1

Pic 3, a zoom out of the machine as it floods away. yes..that is one heck of a vise you can sure throw out the back moving it around!

Pic 4, you can see the square pocket and outline of the dragon submerged under a bath of coolant..yes the coolant looks and smells like antifreeze and it's pretty sticky too. Eventually when the outside is all finished the machine will move into the inside of the dragon and cut more pockets.

I thought maybe my camera could do a few minutes of video, but nope, doesn't do that..all I can show is some pics of my fun. I have lots to learn, but at least I feel I made it to the base of the mountain.