You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

12 X .75 METRIC tap and die sloppy fit

- Thread starter JLL

- Start date

Signed-In Members Don't See This Ad

Signed-In Members Don't See This Ad

Ed McDonnell

Member

Sloppy is not normal.

12.85 for the tenon isn't right. 11.85?

Measure the drilled hole before tapping to make sure you are not oversizing due to a drilling problem.

Measure the tenon size before cutting the thread and then after. A big reduction in size might indicate your die is too tight, if you are using an adjustable die.

Are you sure you are using M12 x 0.75 for both tap and die?

What material are you cutting threads in?

Ed

12.85 for the tenon isn't right. 11.85?

Measure the drilled hole before tapping to make sure you are not oversizing due to a drilling problem.

Measure the tenon size before cutting the thread and then after. A big reduction in size might indicate your die is too tight, if you are using an adjustable die.

Are you sure you are using M12 x 0.75 for both tap and die?

What material are you cutting threads in?

Ed

Sloppy is not normal.

12.85 for the tenon isn't right. 11.85?

Measure the drilled hole before tapping to make sure you are not oversizing due to a drilling problem.

Measure the tenon size before cutting the thread and then after. A big reduction in size might indicate your die is too tight, if you are using an adjustable die.

Are you sure you are using M12 x 0.75 for both tap and die?

What material are you cutting threads in?

Ed

Opps typo error 11.85 tenon yes adjustable die -aluminum

low_48

Member

Ed is right on. Is the hole to size and round? How sharp is the drill? Do you use a starter drill? If you want dead on, drill undersized and ream to size.

edstreet

Member

edstreet

Member

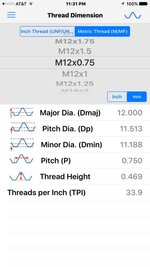

Oh and the tenon should be Dmajor, or 12.000 mm.

Cmiles1985

Member

The big question is: what app is that Ed?

12 X .75 METRIC tap and die sloppy fit - I am using 11.25 drill and a tenon cut at 11.85 - very sloppy not sure why - is this normal ?

Btw this is not a a pen cap fitting - another project - finale detail

Last edited:

edstreet

Member

Does not matter if it's a pen or not.

BSea

Member

I'd also like to know what app that is.

I do think the tenon is too small when using aluminum. Seems like I've heard that an acrylic blank will flex a little when drilling and cutting. So all things being equal, the threads on something like alumilite or ebonite should be a little tighter than threads in aluminum. I think the 1st thing I'd do is do the piece with the tenon again and use 11.95 of maybe even slightly larger. It's true that your hole may be too large too, but I'd make one part, and see if things improve. If so, but you still think there is too much slop, then you can do the other part.

I do think the tenon is too small when using aluminum. Seems like I've heard that an acrylic blank will flex a little when drilling and cutting. So all things being equal, the threads on something like alumilite or ebonite should be a little tighter than threads in aluminum. I think the 1st thing I'd do is do the piece with the tenon again and use 11.95 of maybe even slightly larger. It's true that your hole may be too large too, but I'd make one part, and see if things improve. If so, but you still think there is too much slop, then you can do the other part.

Ed McDonnell

Member

Android: Check out North American Tool's "Tap Hole Size Calculator" in the play store.

Apple: Don't know....don't care....maybe it's there and maybe it's not.

The calcs are pretty simple. Pick up a used machinist handbook and make a little spreadsheet if apple doesn't have a useful app.

Ed

Apple: Don't know....don't care....maybe it's there and maybe it's not.

The calcs are pretty simple. Pick up a used machinist handbook and make a little spreadsheet if apple doesn't have a useful app.

Ed

Very true - never had this problem beforeDoes not matter if it's a pen or not.

duncsuss

Member

Jake, it just occurred to me to ask: what are you using to measure the tenon? Can you trust that measuring tool?

If you have some reference items -- a 12mm drill bit or transfer punch, for example -- check that your calipers are accurate.

If you have some reference items -- a 12mm drill bit or transfer punch, for example -- check that your calipers are accurate.

Curly

Member

I have a couple for the iPhone that I use. There are lots of free or modestly priced apps for machining you just need to poke around a little.

ITAMCO Drill and Tap

iMachinist.

ITAMCO Drill and Tap

iMachinist.