NGLJ

Member

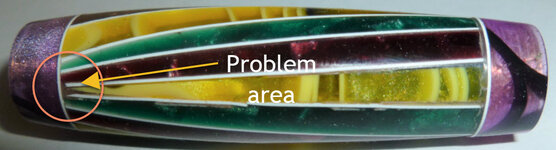

This a follow-up to https://www.penturners.org/threads/acrylic-staves-with-a-twist.173017/. Although adding more staves can improve the appearance it can increase the challenges. For example, the margin for error in drilling at an angle decreases. Even a small deviation from producing 2 faces which are mirror images of each other can result in a turning that is of no use unless you perhaps save the day by adding end pieces. That has been my experience in going from 6 acrylic staves to 12 (made from the offcuts in making the 6). If you get it "spot on" it looks good but if you don't it looks bad! The 6 stave had no plastic spacers which I added for the 12 (see attached). That is a big improvement in appearance and helps to hide the glue lines. See the attached with the circle showing the problem area. Prior to adding end pieces this would have been a total failure. Even now it is not perfect. The opposite face (also shown) looks OK with the end piece, although I did forget to paint the tube  . if you look at the 2 faces you can see how the spacing between the individual staves is quite different. The object in this case is to get them both the same or close. This is not particular to acrylic and the same problem with arise with wood. The advantage of wood is that it is more likely to stay in one piece!

. if you look at the 2 faces you can see how the spacing between the individual staves is quite different. The object in this case is to get them both the same or close. This is not particular to acrylic and the same problem with arise with wood. The advantage of wood is that it is more likely to stay in one piece!

The other aspect of increasing the number of acrylic staves is that it adds more joints to possibly fail, and adding the plastic spacers further increases the chances. Although I used epoxy with the 6 stave it required 3 attempts to drill a hole all the way through, repairing after each failure. The 12 stave was no better and you would expect that, although I did manage it in 2 attempts. It has provided some learning in improving the approach to drilling acrylic staves at an angle. Having to repair no doubt can create some inaccuracy which is enough to create the problem shown. Having said that the 6 stave came out OK and is nearly a mirror image not requiring end pieces to fix. Chance is at play and I need to eliminate chance to get consistency! There is still much more to learn. Having got it to the lathe the 12 stave decided to split into 2 pieces leaving the tube behind, again requiring repair once I actually found the pieces (one was way at the other end of my shop!). Perhaps I need to use stronger epoxy! Thoughts?

Despite the challenges I like the look of the product which I hope will only improve with more experience.

The other aspect of increasing the number of acrylic staves is that it adds more joints to possibly fail, and adding the plastic spacers further increases the chances. Although I used epoxy with the 6 stave it required 3 attempts to drill a hole all the way through, repairing after each failure. The 12 stave was no better and you would expect that, although I did manage it in 2 attempts. It has provided some learning in improving the approach to drilling acrylic staves at an angle. Having to repair no doubt can create some inaccuracy which is enough to create the problem shown. Having said that the 6 stave came out OK and is nearly a mirror image not requiring end pieces to fix. Chance is at play and I need to eliminate chance to get consistency! There is still much more to learn. Having got it to the lathe the 12 stave decided to split into 2 pieces leaving the tube behind, again requiring repair once I actually found the pieces (one was way at the other end of my shop!). Perhaps I need to use stronger epoxy! Thoughts?

Despite the challenges I like the look of the product which I hope will only improve with more experience.