duncsuss

Member

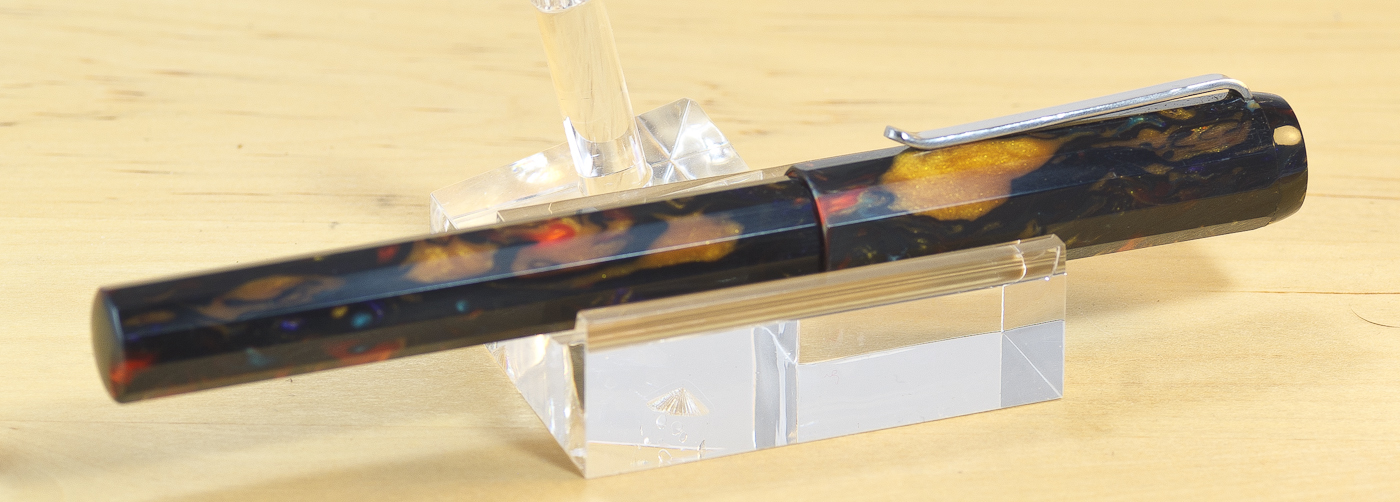

Several years ago I bought a few really nice Alumilite blanks from Wayne Ryan (at that time doing business as Texas Blanks) and figured out how to shave facets on them using a trim-router in the Penn State fluting jig.

I prepped a few this way, then put them on the shelf. I finally got around to making a pen from one set. 12 sides takes a lot of sanding and polishing, it'll be a while before I make any progress on any of the other sets that are in the same semi-prepared condition.

Clip is hand made from 0.050" sheet stainless steel; nib section is made for JoWo #5 nib units.

I prepped a few this way, then put them on the shelf. I finally got around to making a pen from one set. 12 sides takes a lot of sanding and polishing, it'll be a while before I make any progress on any of the other sets that are in the same semi-prepared condition.

Clip is hand made from 0.050" sheet stainless steel; nib section is made for JoWo #5 nib units.