wade45

Member

Well, this makes things a whole lot more interesting.

Finished parts that need to be reworked. Or touched upOkay, I'll ask...

Why?

where did you get the rubber collet?

Hmm, pretty good idea. When I have a need, I have been wrapping the part in blue painters tape, just one time around and so far so good.Finished parts that need to be reworked. Or touched up

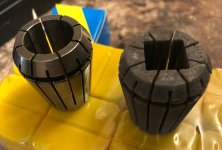

TPU is too soft for longevity.Looks to me like it may have been 3D printed with TPU. If so, I'd love to know where you found the 3D model file.

What material did you print them with?Blue tape is what I have used but cad design and printing is free.

I did a TPU and rubber like resin from elegoo.What material did you print them with?

TPU works great as far as grip it's the longevity that I'm concerned with.The idea could have potential.

I have designed collets in CAD and 3d printed them.

I made this one years ago in PLA on my old ender 3 printer for square blanks

I haven't had access to lathes for a while but I have a new desktop CNC on order.

I might revisit 3d printing collets in something like TPU and see how that works.

View attachment 389796View attachment 389797View attachment 389798View attachment 389799View attachment 389800View attachment 389801View attachment 389802

TPU is a flexible filament. ^

I can't, it goes against company rules.Looks interesting! I'm not sure that I would use it much - also a blue tape user - but I'd give it a try. Share the STL?

Kevin

I've got the files available on my Patreon. I also can print them in TPU or PLA on demand for $ if someone wants one and doesn't have a 3d printer.Looks interesting! I'm not sure that I would use it much - also a blue tape user - but I'd give it a try. Share the STL?

Kevin

I am sorry - I didn't realize your post was a camouflaged advertisement for your firm's products.I can't, it goes against company rules.

Wade

Kevin,I am sorry - I didn't realize your post was a camouflaged advertisement for your firm's products.

Kevin