spaceengravers

Member

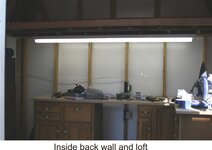

Finally got permission to build my workshop! Unfortunately it's going to be pretty small (11x12) but I think I will have a little more room than I had in the garage with the car and motorcycle crowding me in...plus it will be a dedicated area! I'm building it with the barn style roof so I can put a loft in it for storage...this helped me get my permission from the "boss"..."but honey, I can clean out the garage and the basement and store it in the loft..." I build in a 3 ft loft at one end and a 2 ft loft in the other end. Put the insulation on today...Gotta wait a few more days (dang work getting in the way) to put on the siding and trim...then I'll start working on the inside...

Here's some pics of it so far.

Mike

Here's some pics of it so far.

Mike