Joebobber

Member

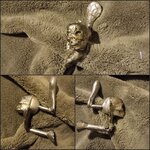

My oldest son got a smelting kit for Christmas so we've been melting down everything. We tried to sand cast a skull from a carved rock skull and it turned out ok. We did 2 more and I drilled and tapped then to fit the knobs on my drill press.

Is it possible to do pens/pen parts from just sand casting or do we need to do a lost wax or lost styrofoam?

Anyway, its been alot of fun. We took apart my old ice auger and pressure washer and a few other things along with pop cans. We just got up the nerve to do some brass.

Is it possible to do pens/pen parts from just sand casting or do we need to do a lost wax or lost styrofoam?

Anyway, its been alot of fun. We took apart my old ice auger and pressure washer and a few other things along with pop cans. We just got up the nerve to do some brass.