WriteON

Member

Giving some thought but only daydreaming for now.... comments on this set up. Thanks, Frank

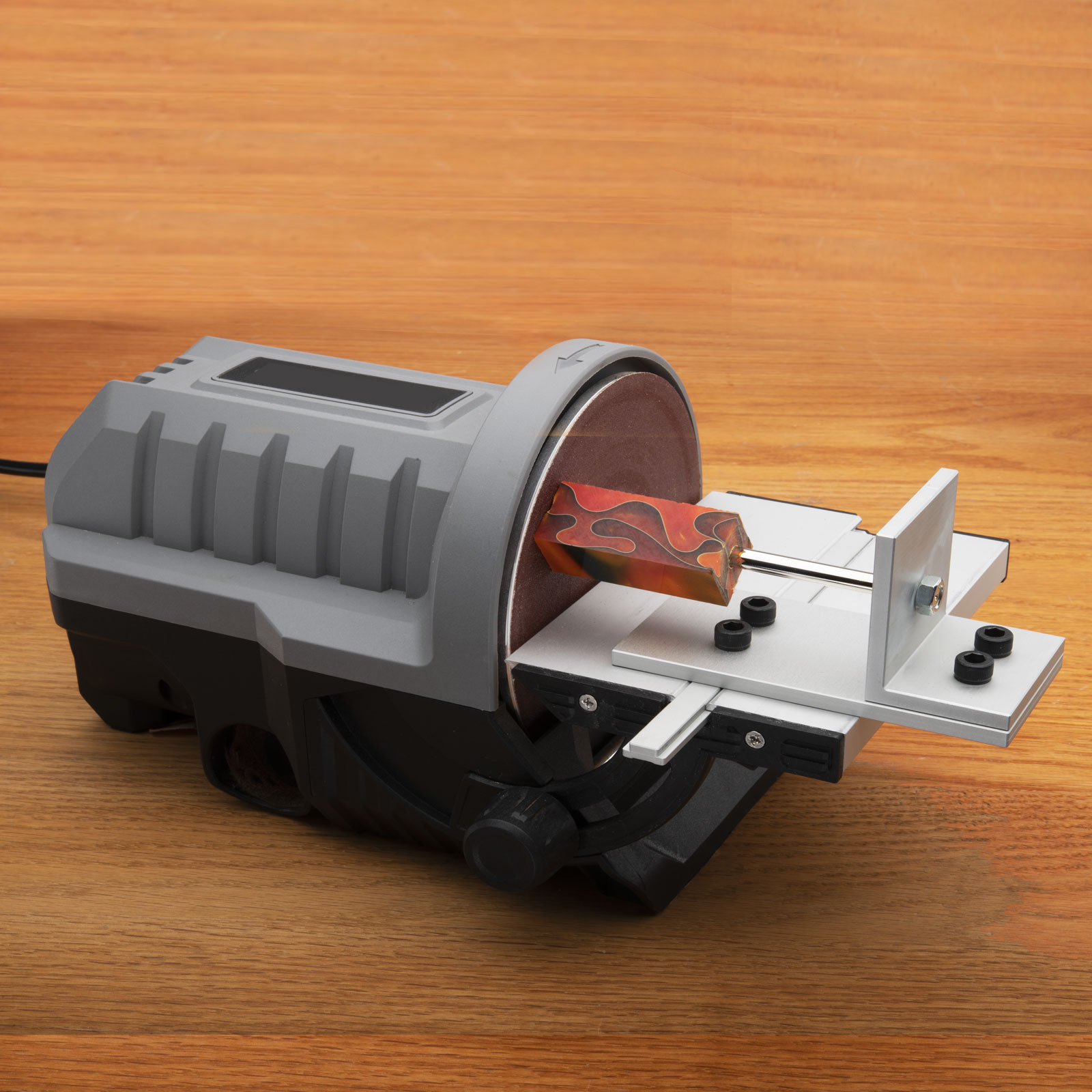

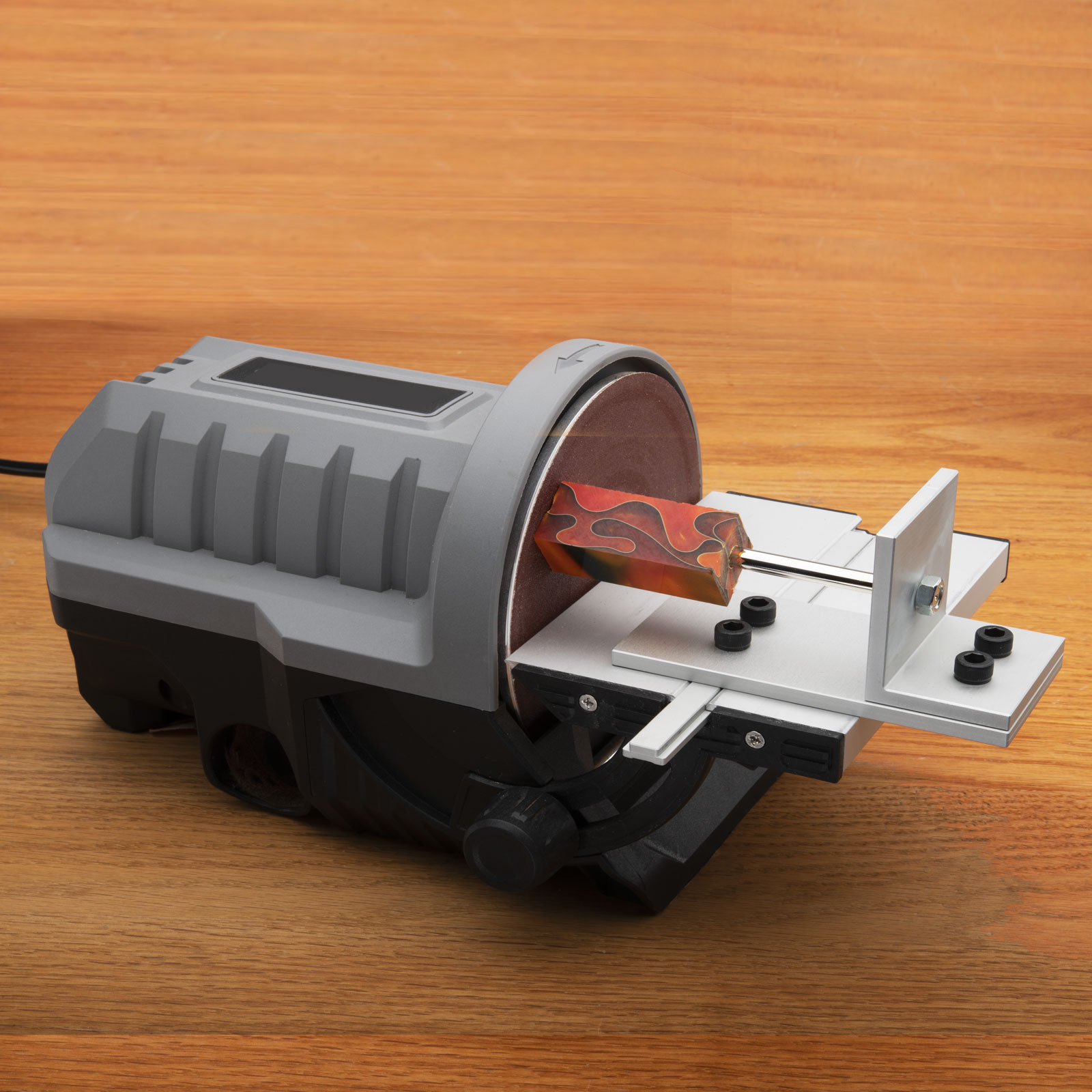

5in. Benchtop Disc Sander/Barrel Squaring System

Here is a fresh, dedicated solution to sand and square your pen blanks precisely, every time; with less tear out on testy materials. With this combination disc sander and barrel squaring cross slide jig you just slide your blank into the rotating disc to square your blank. The sander alone can also

www.pennstateind.com