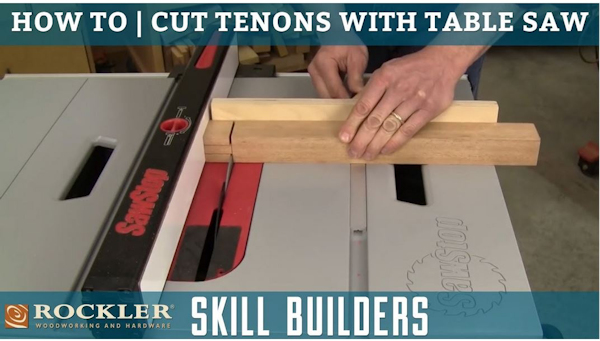

I received the below image in an email ad this morning. I've seen it multiple times. What am I missing here? I thought it was bad practice to trap a workpiece on two sides. Fence or miter gage, but not both. My process has been to press the workpiece against a stop block attached to the fence behind the blade. Then the workpiece is clear of the stop block when it engages the blade.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

General Woodworking Question - Tenons

- Thread starter jeff

- Start date

Signed-In Members Don't See This Ad

Signed-In Members Don't See This Ad

Yup, just asking for a kickback. I clamp a scrap piece of wood to my fence, to use as a stop and then when you make your cut there is a gap between your wood and the fence.

jttheclockman

Member

There is nothing wrong with what he is doing if he is making tenons. There is no pieces being cut off that can be trapped between the piece and the fence. The shoulders are cut off using a different jig to hold the piece upright. He could skip that part if he used a dado blade and made a couple passes but again you are cutting and the only thing left behind is sawdust.

There is a caveat to this method and that is the fence must be in tune with the mitergauge. If you are like some woodworkers you tend to skew the fence just a tad away from the blade at the back end. This helps prevent kickbacks. Now if you continue to push the piece against the fence as you are cutting then the piece could have an ever so slight slant to the cut. Now on longer tenons that could be a problem. On short tenons like that you probably would never see it depending on the skewing of the fence. Now away around that and just use the fence and miter is to lock the piece against the miter gauge and use the fence as a stop block sort of. It is actually better to lock it down so no movement messes with the cuts and thus I use a sled for that.

I take out the slight chance of the fence not being 100% in line with the gauge by using the stop block as you do Jeff.

Yes it is not safe to cut off small pieces and trap them between fence and piece. That would lead to kickback.

There is a caveat to this method and that is the fence must be in tune with the mitergauge. If you are like some woodworkers you tend to skew the fence just a tad away from the blade at the back end. This helps prevent kickbacks. Now if you continue to push the piece against the fence as you are cutting then the piece could have an ever so slight slant to the cut. Now on longer tenons that could be a problem. On short tenons like that you probably would never see it depending on the skewing of the fence. Now away around that and just use the fence and miter is to lock the piece against the miter gauge and use the fence as a stop block sort of. It is actually better to lock it down so no movement messes with the cuts and thus I use a sled for that.

I take out the slight chance of the fence not being 100% in line with the gauge by using the stop block as you do Jeff.

Yes it is not safe to cut off small pieces and trap them between fence and piece. That would lead to kickback.

Last edited:

I wasn't thinking about small pieces. I agree cheeks are cut after. I was referring to the workpiece cocking due to catching on the fence.There is nothing wrong with what he is doing if he is making tenons. There is no pieces being cut off that can be trapped between the piece and the fence. The shoulders are cut off using a different jig to hold the piece upright. He could skip that part if he used a dado blade and made a couple passes but again you are cutting and the only thing left behind is sawdust.

Yes it is not safe to cut off small pieces and trap them between fence and piece. That would lead to kickback.

jttheclockman

Member

I was adding some points to my original reply when you posted this. If your wood catches on the fence then you have a larger problem and need to address the surface of the fence. His is smooth as a baby's bottom. To prevent the scenario you mention and still use his setup then it is good to use a sled where you can lock the piece against the miter.I wasn't thinking about small pieces. I agree cheeks are cut after. I was referring to the workpiece cocking due to catching on the fence.

Again I am adding points here. It is actually a good idea to always lock the piece down because even if you use a stop block as you mention the piece can creep forward on you as you push past blade. I have had this happen to me and thus the sled and toggle clamps now. With his method if the fence is 100% true to the gauge then he eliminates that problem because it can not creep But then you have to be aware to tightly hold the piece against the miter gauge. These are my thoughts.

Last edited:

I was adding some points to my original reply when you posted this. If your wood catches on the fence then you have a larger problem and need to address the surface of the fence. His is smooth as a baby's bottom. To prevent the scenario you mention and still use his setup then it is good to use a sled where you can lock the piece against the miter.

Again I am adding points here. It is actually a good idea to always lock the piece down because even if you use a stop block as you mention the piece can creep forward on you as you push past blade. I have had this happen to me and thus the sled and toggle clamps now. With his method if the fence is 100% true to the gauge then he eliminates that problem because it can not creep But then you have to be aware to tightly hold the piece against the miter gauge. These are my thoughts.

Clamping the workpiece to the miter gauge would be one good solution.

carlmorrell

Member

I have made a lot of furniture. Used to swear by mortise and tenon. One project I did, tenons were going to be a problem, so I used a double mortise with a spline. It made the process so much simpler. Since then, I have never made a tenon. I know there are places for them, but IMO, not really necessary for most small to medium furniture. If I am joining 3/4" stock, I use 1/4" BB plywood for the spline. Better than a biscuit, 8 times easier than a tenon.

Having trouble visualizing that. Got a pic or sketch?I have made a lot of furniture. Used to swear by mortise and tenon. One project I did, tenons were going to be a problem, so I used a double mortise with a spline. It made the process so much simpler. Since then, I have never made a tenon. I know there are places for them, but IMO, not really necessary for most small to medium furniture. If I am joining 3/4" stock, I use 1/4" BB plywood for the spline. Better than a biscuit, 8 times easier than a tenon.

jttheclockman

Member

Basically he made 2 pockets. One in each piece and infilled with a spline. Many people at one time used a biscuit cutter to do this. Now they can use a router.Having trouble visualizing that. Got a pic or sketch?

Curly

Member

Jeff you are correct it isn't best practice. Clamping a block to the fence as you said is good, as is a longer board on the mitre gauge with a stop block or use a sled with one or clamps. If the saw is setup properly they will get away with it but people will push the idea beyond limits and possibly get hurt.

carlmorrell

Member

My hand drawing was too sloppy. I googled and found this:Having trouble visualizing that. Got a pic or sketch?

Mortise Spline - Arched Moldings - Woodworking Archive

Typically, when I have to build a frame, the joint I would choose first is a mortise and tenon. Although mortise and tenon joints could be used for the frames

penicillin

Member

- Joined

- Feb 27, 2019

- Messages

- 1,036

Non-through Crosscut:

The end of a workpiece may be held against the fence for a non-through crosscut. The non-through crosscut shown in the photo in the original post is safe. You can see that the woodworker is using a riving knife in the photo. A riving knife increases safety.

Through Crosscut:

The end of a workpiece must not be held against the fence for a through crosscut. This could result in a kickback. For a through crosscut on your table saw, clamp a stop block to the fence in front of the blade. When the cutting starts, that part of the workpiece should be beyond the stop block, in "open space" on the table saw. Guide the cut with a miter gauge, miter fence, or sled.

Edit:

P.S. It may be worthwhile to watch the actual video, here:

https://www.youtube.com/watch?v=4CvMccfXKnk

The end of a workpiece may be held against the fence for a non-through crosscut. The non-through crosscut shown in the photo in the original post is safe. You can see that the woodworker is using a riving knife in the photo. A riving knife increases safety.

Through Crosscut:

The end of a workpiece must not be held against the fence for a through crosscut. This could result in a kickback. For a through crosscut on your table saw, clamp a stop block to the fence in front of the blade. When the cutting starts, that part of the workpiece should be beyond the stop block, in "open space" on the table saw. Guide the cut with a miter gauge, miter fence, or sled.

Edit:

P.S. It may be worthwhile to watch the actual video, here:

https://www.youtube.com/watch?v=4CvMccfXKnk

Last edited:

greenacres2

Member

I appreciate that a non-through crosscut would be "safe"--but it only takes a small split in the end grain to change it from non-through to partially or fully through. I'll keep running off the 1.00" thick piece of Ipe clamped to my fence. Love my fingers, kind of attached to them, really want to keep it that way!!

earl

earl