Alan Morrison

Member

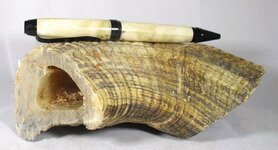

A nearby vet, whose hobby is making shepherds crooks, gave me his offcuts of the rams horns that he uses for the crook.

The pen was finished up to 600 grit, then buffed with Tripoli and White Diamond. Polished up with Ren. wax.

I would be grateful for other peoples way to finish this material.

Many thanks. Alan.

The pen was finished up to 600 grit, then buffed with Tripoli and White Diamond. Polished up with Ren. wax.

I would be grateful for other peoples way to finish this material.

Many thanks. Alan.