mark james

IAP Collection, Curator

The basic design of the oval and inner element has a long history on IAP, so I take no credit. Searches will find examples from rherrell, Skiprat, ldb2000 and more recently Dale Parrott. They referred to their designs as "Windows", "Ellipses, and Window Style respectively. My design is a variation on all, but takes the most inspiration from Dale's design. I have worked on this on and off for over a year, and it represents my "Coronavirus" bucket list design.

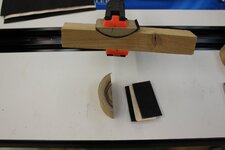

The cross/spectraply inlay I made on a different set of pens last year, and always wanted to figure out how to have it in an oval "window." Inspirational hint: Whenever I have a new idea - I research what others have done; it probably has been done! So the oval concept is not mine, but I did get creative for the inlay.

I call this design a "Picture Window" as that is my intent, to use the "Window" as the frame for a variety of future inlays. I have 9 decent picture designs to play with, so far...

I might add, this had a significant learning cure for me, and a lot of tweaking still needs to be worked on.

Stay healthy folks!

The cross/spectraply inlay I made on a different set of pens last year, and always wanted to figure out how to have it in an oval "window." Inspirational hint: Whenever I have a new idea - I research what others have done; it probably has been done! So the oval concept is not mine, but I did get creative for the inlay.

I call this design a "Picture Window" as that is my intent, to use the "Window" as the frame for a variety of future inlays. I have 9 decent picture designs to play with, so far...

I might add, this had a significant learning cure for me, and a lot of tweaking still needs to be worked on.

Stay healthy folks!