qquake

Member

Has anybody turned one of these blanks? Are they "chippy" like the money blanks? Those were a bear. I ended up using a carbide chisel, and 100 grit for final shaping. Any hints or tips? It's an expensive blank, if I ruined it I would cry. A friend of mine is getting married, and this is what she chose for her wedding pen. Is it laser engraveable after it's turned?

www.exoticblanks.com

www.exoticblanks.com

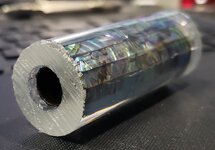

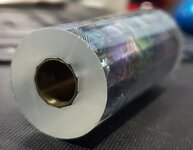

Paua Abalone Shell Pen Blank - Sierra - Mexican Green Heart #2455

Mexican Green Heart Abalone – This blank is made with the heart (center) of beautiful Paua Abalone species called Mexican Green. This heart shell is comprised of pastels with green accents along with flashes of pinks blues and purples. It also tends to have more of a ripple look. This blank is...