You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

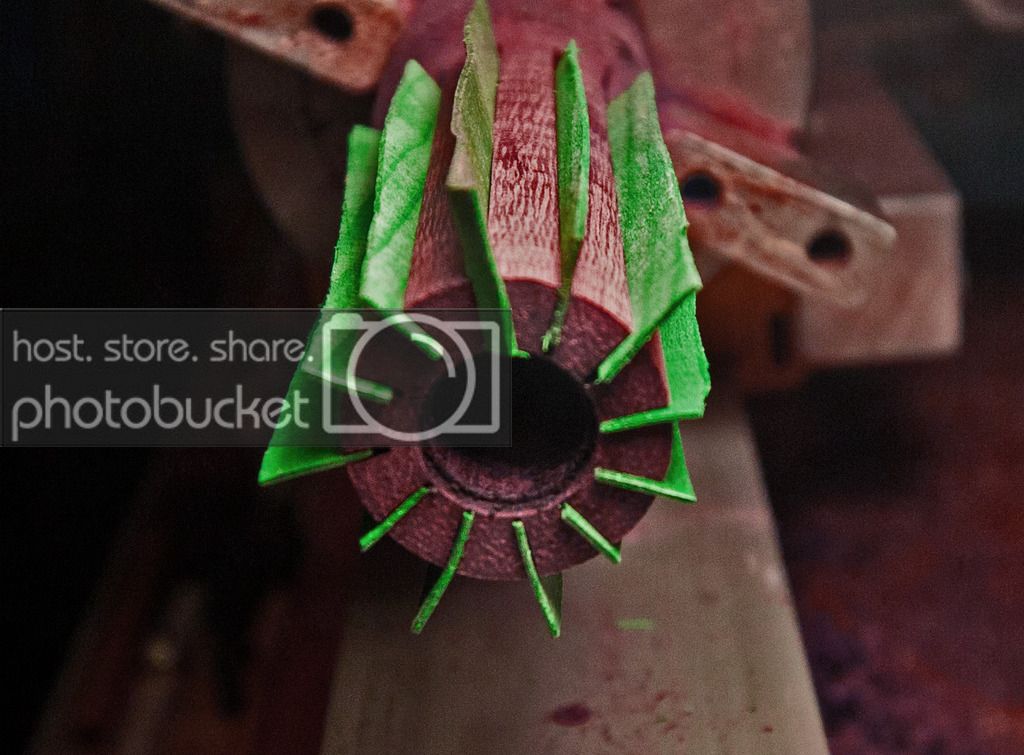

So what is wrong in this photo ?

- Thread starter farmer

- Start date

Signed-In Members Don't See This Ad

Signed-In Members Don't See This Ad

It appears that the model is wearing Camoflage!! They are using some serious stealth tactics, as I can't see anything

Is the brass tube already inside the blank?

Wrong

Sorry no brass tube installed yet.

Is the brass tube already inside the blank?

Sorry no brass tube installed yet.

TomW

Member

The kerfs are not radial, therefore the finished segments will vary in width....?

jttheclockman

Member

Depth of cuts vary. Blank is either not true or sitting on a bias.

another photo

The problem is not inside the purple heart fluted dowel .

The ridge inside was caused because I changed Forstner Bits

My first Forstner Bit that I used to bore the hole was dull.

Noticing that I changed bits, to a shaper Forstner bit but didn't know it would leave that ridge .

But that's not the problem that I am seeing .

A hint is the blade smoked going in.

I have just switched from using a dremel to cut these slits or slots.

To using a Ridgid veneer trimer so I really don't know what normal is for these extremely small blades .

Here is a better view of the bore .

This going to be trim rings .

The fluted wood will be parted off into rings or washers ..

The issue is with the cutter

The problem is not inside the purple heart fluted dowel .

The ridge inside was caused because I changed Forstner Bits

My first Forstner Bit that I used to bore the hole was dull.

Noticing that I changed bits, to a shaper Forstner bit but didn't know it would leave that ridge .

But that's not the problem that I am seeing .

A hint is the blade smoked going in.

I have just switched from using a dremel to cut these slits or slots.

To using a Ridgid veneer trimer so I really don't know what normal is for these extremely small blades .

Here is a better view of the bore .

This going to be trim rings .

The fluted wood will be parted off into rings or washers ..

The issue is with the cutter

Last edited:

Depth

The depth is a little off but I can live with that .

That's not the problem. I am talking about.

Depth of cuts vary. Blank is either not true or sitting on a bias.

The depth is a little off but I can live with that .

That's not the problem. I am talking about.

jttheclockman

Member

Well if you have used purpleheart before you would know it is an oily very dense wood and any cutting tool will cause heat from the friction and it will smoke. I always had a hard time scrolling that wood that I rarely do it any more. It burns the cuts. It will dull cutting blades very fast as well. The thinner the blade and less set in the teeth will really have problems. many many other woods out there that will do the same.

Blade

Your right about purple heart being oily , but that is not the problem I see .

What else will make a saw blade smoke wood ?

Well if you have used purpleheart before you would know it is an oily very dense wood and any cutting tool will cause heat from the friction and it will smoke. I always had a hard time scrolling that wood that I rarely do it any more. It burns the cuts. It will dull cutting blades very fast as well. The thinner the blade and less set in the teeth will really have problems. many many other woods out there that will do the same.

Your right about purple heart being oily , but that is not the problem I see .

What else will make a saw blade smoke wood ?

jjjaworski

Member

Looks like the saw blade is on backwards

lorbay

Member

Is it you are cutting on the opposite side of the lathe. ???

Lin.

Lin.

A winner

Funny how pouring over pictures shows things we had not seen with out naked eye's and how everyone sees something different .

I can believe I got that clean of cuts with the blade on backwards ..

Cant believe I put the blade on backwards :frown:

Good eye Mr jjjaworski

Looks like the saw blade is on backwards

Funny how pouring over pictures shows things we had not seen with out naked eye's and how everyone sees something different .

I can believe I got that clean of cuts with the blade on backwards ..

Cant believe I put the blade on backwards :frown:

Good eye Mr jjjaworski

jttheclockman

Member

Well I will stay away from all the obvious because this is not your first time doing this. I am sure you have cut these using this saw and cutting the exact same way before.

With that said I still say it is the blade of that saw. There is no set or such a small set in the teeth to clear debris when being cut. If the blade is sharp again an obvious thing. I get this all the time with a scroll saw blade. The amount of teeth turning in a tight slot creates heat. If there is any stress left in that piece from not being totally dried it will close around the blade even more so. If you have done this with this wood before have you had the same problem??? If this is the first time working with the wood this is what to expect.

You are showing so many other pieces cut and filled I am not following what it is you want to know. You obviously have done this before just from the other photos. Did the blade smoke in the other examples???

Wow well you answered in your last post. Good luck and that one is on you:biggrin::biggrin::biggrin:

With that said I still say it is the blade of that saw. There is no set or such a small set in the teeth to clear debris when being cut. If the blade is sharp again an obvious thing. I get this all the time with a scroll saw blade. The amount of teeth turning in a tight slot creates heat. If there is any stress left in that piece from not being totally dried it will close around the blade even more so. If you have done this with this wood before have you had the same problem??? If this is the first time working with the wood this is what to expect.

You are showing so many other pieces cut and filled I am not following what it is you want to know. You obviously have done this before just from the other photos. Did the blade smoke in the other examples???

Wow well you answered in your last post. Good luck and that one is on you:biggrin::biggrin::biggrin:

Last edited:

TomW

Member

Of course backwards is relative to rotation...not enough data to determine that...

jttheclockman

Member

Of course backwards is relative to rotation...not enough data to determine that...

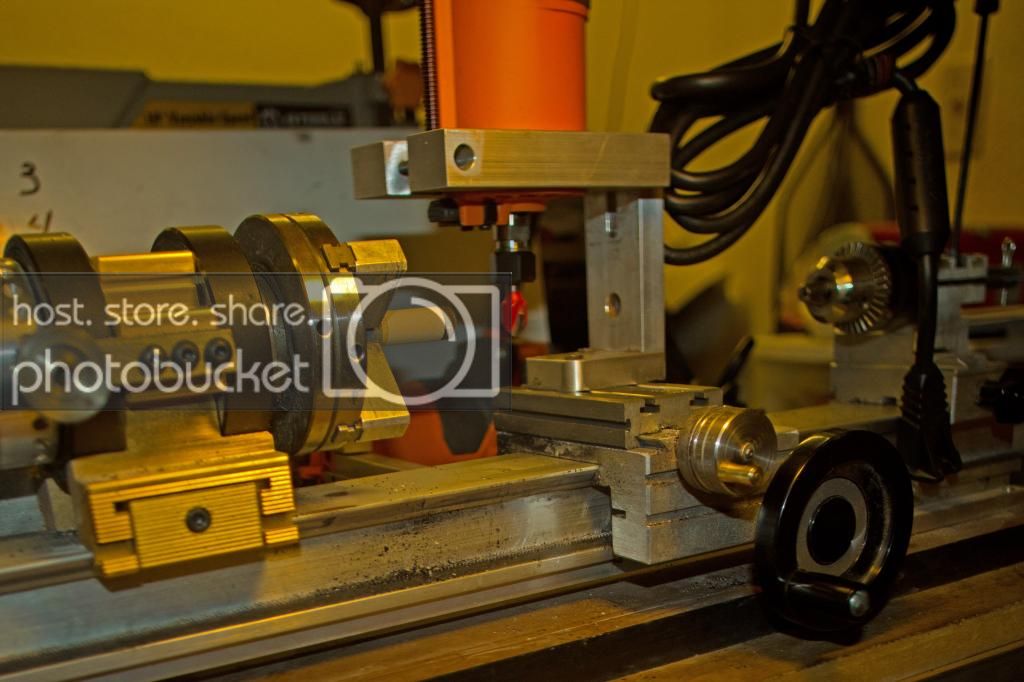

Have to agree with this statement too. Look at this photo of his. The blade is looking the same way. Different posting.

http://i1110.photobucket.com/albums/h454/mortuarymike/Bouble 8 1_zpseyo0amcz.jpg

Cwalker935

Member

Believe it or not but I thought the blade may have been on backward because of the swirl pattern on the blade. I know, it's easy to claim that after you provided the answer. I watched my grandfather drill a hole through metal with his drill in reverse one time, I have been acutely aware of the direction of rotating tools ever since I heard some of the words that came out of his mouth almost 50 years ago once he realized what he had done. Big impression on little ears.

leehljp

Member Liaison

The blade is on backwards to the feed direction. Shucks, I have done that on a table saw before!

Ahh, I posted this from seeing page 1, while the answer was on page 2.

Ahh, I posted this from seeing page 1, while the answer was on page 2.

Last edited:

jttheclockman

Member

The blade is on backwards to the feed direction. Shucks, I have done that on a table saw before!

Ahh, I posted this from seeing page 1, while the answer was on page 2.

How do you know what is the feed direction. As I shown in his other picture the blade is the same way.

If he started the cut from the open end and wet toward the headstock than yes. If he started at the headstock and worked out then it could be the other way.:biggrin: Now this is with the router on the side of the work piece as he shows. Put it on the other side and all reverses. Having fun yet.

Last edited:

leehljp

Member Liaison

The blade is on backwards to the feed direction. Shucks, I have done that on a table saw before!

Ahh, I posted this from seeing page 1, while the answer was on page 2.

How do you know what is the feed direction. As I shown in his other picture the blade is the same way.

If he started the cut from the open end and wet toward the headstock than yes. If he started at the headstock and worked out then it could be the other way.:biggrin: Now this is with the router on the side of the work piece as he shows. Put it on the other side and all reverses. Having fun yet.

The answers are obvious from the picts in posts #3 & #11 AND the "smoke" hint. Smoke can come from a number of reasons, but the most obvious and common are reversed blades. I learned that in EXPERIENCE Class 101 and Class 101R (remedial). :biggrin:

Yes, there are many "possibilities" but in reality not many probabilities (just one). I made one of those pens in 2007. Believe me, all possibilities are still in my mind. To me, Probabilities and possibilities are on opposite ends of the spectrum, with "probabilities" being reduced to one, when accompanied by such picts and the hint of smoke. :biggrin:

jalbert

Member

The blade was spinning clockwise, and the blade was on the wrong side of the blank so the teeth weren't actually cutting?

jttheclockman

Member

Well I guess he will not do that again. :biggrin:

That Again

LOL I don't know if I would bet that.

Well I guess he will not do that again. :biggrin:

LOL I don't know if I would bet that.

Paul in OKC

Member

It is only backwards if your spindle only turns one way! Other wise just reverse the spindle

cutter spindle

Spindle ( ridged veneer trimmer ) Doesn't have reverse as said it only turns clock wise .

It is only backwards if your spindle only turns one way! Other wise just reverse the spindle

Spindle ( ridged veneer trimmer ) Doesn't have reverse as said it only turns clock wise .

It's hard to tell on my monitor screen, but are the blade and arbour off vertical, so that the blade can't make true perpendicular cuts to the axis of the blank? If so, how are you holding the arbour - what fitting does it have, MT, R8, a chuck?

It's hard to tell on my monitor screen, but are the blade and arbour off vertical, so that the blade can't make true perpendicular cuts to the axis of the blank? If so, how are you holding the arbour - what fitting does it have, MT, R8, a chuck?

1/4 shank

https://www.cuesmith.com/jeweler-s-sawand-1-4-arbor.html

Last edited:

TurtleTom

Member

Depth of cuts vary. Blank is either not true or sitting on a bias.

The depth is a little off but I can live with that .

That's not the problem. I am talking about.

It looks to me like the cutter is not centered vertically.