endacoz

Member

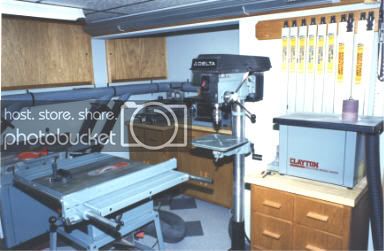

I was given this Delta 3/4 horse power top of barrel dust collector. I used it occasionally but need to come up with something I will use more often. My first thought was to just replace the bag that is on it that leaks some dust. Looking for 5 micron or better. I need to replace the hose as it is old and has many holes and cracks in it. The previous owner put a 4 inch to 1.5" adapter that I don't want. I'd like to keep it 4 inch as my band saw is also 4 inch. the wheels on it works fairly well. So there's no excuse for me not to be using it. Mostly I'm looking to use it on my lathe. So I should have a set up with a hood mounted to my lathe stand that I could just hook the DC hose up to. Suggestions for lathe hood hookup / setup.

then after reading other forums posts on the IAP, I like the looks of the Rockler 21 foot expandable retractable hose attachment. so basically my main question is is it worth repairing this Delta dust collector or selling it and getting the harbor Freight 1 mounting it on the wall and getting the rock layer 21 foot hose?

Portable Dust Collector - 13 Gallon.

Dust Right Expandable Hose-Expandable Hose | Rockler Woodworking Tools

Either way I still need to get a set up at least on my main leave for a dust hood and mount.

then after reading other forums posts on the IAP, I like the looks of the Rockler 21 foot expandable retractable hose attachment. so basically my main question is is it worth repairing this Delta dust collector or selling it and getting the harbor Freight 1 mounting it on the wall and getting the rock layer 21 foot hose?

Portable Dust Collector - 13 Gallon.

Dust Right Expandable Hose-Expandable Hose | Rockler Woodworking Tools

Either way I still need to get a set up at least on my main leave for a dust hood and mount.