jttheclockman

Member

I saw the thread on barrel trimmers and it got me thinking.

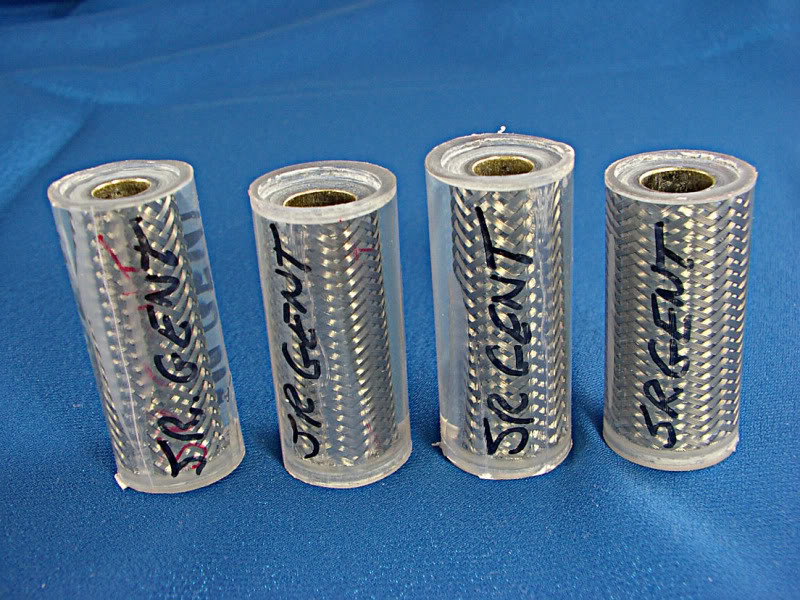

At one time there was a member here Nolan who use to take HSS cutter and turn them into carbide cutters. At that time I bought 2 from him and have used them ever since but it seems I lost one some time ago ( have no idea where it is) Does anyone still make them or can you buy a 4 or 6 blade carbide cutter anywhere?? They are the only trimmers I would use.

Does anyone still make them or can you buy a 4 or 6 blade carbide cutter anywhere?? They are the only trimmers I would use.

At one time there was a member here Nolan who use to take HSS cutter and turn them into carbide cutters. At that time I bought 2 from him and have used them ever since but it seems I lost one some time ago ( have no idea where it is)