mark james

IAP Collection, Curator

Due to allergies, this project came into being. I suspect it may be useful for anyone who may develop sensitivities to resins after they have been casting for awhile and may want to try to continue, so there may be more application. Additionally, it may be useful for those who use PR (which I do not) as I've read that the odors can be strong.

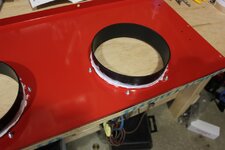

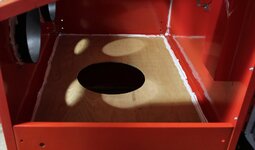

I started with a Harbor Freight 40 lb sand blasting cabinet. (May, 2014: $299; sale price $210; additional 20% off = $168). Extras: silicone caulking, 3/4" gasket tape; 6 LED puck lights; copper fittings; blue flex tube for air vent; Air vent/duct for garage wall; a battery operated air mattress pump; various fittings to reduce hoses and pipes from the box, to pump, to wall junction; probably a few other minor things.

My objectives:

1. Sealed as well as possible to prevent exposure from fumes on my skin.

2. Have a slow continous air draw out from the box venting through a wall.

3. Be able to have enough inside work space to mix and cast and store

all supplies.

4. Pass inspection from SWSBO!

Inspection went as expected... I failed!

Last 2 items required: Better gloves. The included gloves are actually deemed very good, but may be gas permeable are questionable, so SWSBO will order me some of her preference . And it was suggested to have a 1 3/4" air hose for air in from the outside wall, and seal all last junctions and the hole in the back where the compressor hose has bee threaded. I had thought that all forward joints were sealed directly in front of me, and that the back accesses could be OK to allow air in and help with the continous air draw... This was not acceptable.

. And it was suggested to have a 1 3/4" air hose for air in from the outside wall, and seal all last junctions and the hole in the back where the compressor hose has bee threaded. I had thought that all forward joints were sealed directly in front of me, and that the back accesses could be OK to allow air in and help with the continous air draw... This was not acceptable.

If this is of any interest - ask any questions.

I need to wait a few more days to test and do some casting.

I started with a Harbor Freight 40 lb sand blasting cabinet. (May, 2014: $299; sale price $210; additional 20% off = $168). Extras: silicone caulking, 3/4" gasket tape; 6 LED puck lights; copper fittings; blue flex tube for air vent; Air vent/duct for garage wall; a battery operated air mattress pump; various fittings to reduce hoses and pipes from the box, to pump, to wall junction; probably a few other minor things.

My objectives:

1. Sealed as well as possible to prevent exposure from fumes on my skin.

2. Have a slow continous air draw out from the box venting through a wall.

3. Be able to have enough inside work space to mix and cast and store

all supplies.

4. Pass inspection from SWSBO!

Inspection went as expected... I failed!

Last 2 items required: Better gloves. The included gloves are actually deemed very good, but may be gas permeable are questionable, so SWSBO will order me some of her preference

If this is of any interest - ask any questions.

I need to wait a few more days to test and do some casting.

Attachments

-

IMG_0828.jpg128.7 KB · Views: 156

IMG_0828.jpg128.7 KB · Views: 156 -

IMG_0829.jpg152.6 KB · Views: 138

IMG_0829.jpg152.6 KB · Views: 138 -

IMG_0830.jpg161.8 KB · Views: 145

IMG_0830.jpg161.8 KB · Views: 145 -

IMG_0831.jpg133 KB · Views: 188

IMG_0831.jpg133 KB · Views: 188 -

IMG_0827.jpg202.2 KB · Views: 172

IMG_0827.jpg202.2 KB · Views: 172 -

IMG_0836.jpg115.7 KB · Views: 148

IMG_0836.jpg115.7 KB · Views: 148 -

IMG_0835.jpg173.4 KB · Views: 143

IMG_0835.jpg173.4 KB · Views: 143 -

IMG_0834.jpg136.8 KB · Views: 169

IMG_0834.jpg136.8 KB · Views: 169 -

IMG_0833.jpg104.3 KB · Views: 147

IMG_0833.jpg104.3 KB · Views: 147 -

IMG_0832.jpg136 KB · Views: 140

IMG_0832.jpg136 KB · Views: 140 -

IMG_0837.jpg251 KB · Views: 165

IMG_0837.jpg251 KB · Views: 165 -

IMG_0838.jpg184.3 KB · Views: 162

IMG_0838.jpg184.3 KB · Views: 162 -

IMG_0839.jpg148.8 KB · Views: 171

IMG_0839.jpg148.8 KB · Views: 171 -

IMG_0840.jpg189.8 KB · Views: 154

IMG_0840.jpg189.8 KB · Views: 154 -

IMG_0841.jpg302.1 KB · Views: 164

IMG_0841.jpg302.1 KB · Views: 164