Justturnin

Member

A little bit about I ask what type of wheels I should use for my steady. Well I ran to lowes and found some shower door rollers that worked.

Here they are.

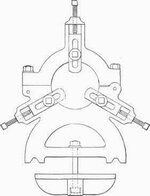

I don't know CAD or anything like that so a lot of my "design" is a quick sketch and then some measurements on the piece I will be cutting. I did this on 1/2" MDF. Here is a pic of the Top and the base.

All the pieces cut out...

I used a 4" Holesaw to cut the center and a 1/4" straight router bit and my ryobi palm router to cut the slot (they were freehand and are straight enough for the prototype....:redface

I used some 1/2"x1/8"x6" (could have used 4.5") angle iron for the arm. I would have used tubing but I need to be able to tap them or weld a nut on it. No welding rig so I went w/ Angle Iron. Not pictured, sorry, I drilled a 11/64 hole at the tip to hold the roller that used 8x32 screws and then I drilled and tapped 3 holes at the 2", 3" & 4" marks. I have a shop smith so I set it up to drill horizontally and made a quick jig w/ scraps to support the drilling.

I glued, nailed and screwed it together. Not shown, I borrowed my knob and bracket off of my Jamison Hollowing Rig to hold it down. I forgot to buy the iron to make one so it will do until I find myself in lowes again. You can see why I drilled 3 holes. I keep my tightening knob (1.5" piece of 1/4"x20 all-thread and a knob and some med CA) in the center and can move the other 1/4x20 bolt to the top or bottom depending on whether I need it for a smaller or larger piece. The 2nd bolt just keeps it from wondering.

I am thinking about making the final out of some sort of plastic be it PVC or UHMW. If you have an opinion on that please let me know.

My materials cost about $30 (already had the MDF). Much was unnecessary but I opened them before I realized this so I now own them.

Here they are.

I don't know CAD or anything like that so a lot of my "design" is a quick sketch and then some measurements on the piece I will be cutting. I did this on 1/2" MDF. Here is a pic of the Top and the base.

All the pieces cut out...

I used a 4" Holesaw to cut the center and a 1/4" straight router bit and my ryobi palm router to cut the slot (they were freehand and are straight enough for the prototype....:redface

I used some 1/2"x1/8"x6" (could have used 4.5") angle iron for the arm. I would have used tubing but I need to be able to tap them or weld a nut on it. No welding rig so I went w/ Angle Iron. Not pictured, sorry, I drilled a 11/64 hole at the tip to hold the roller that used 8x32 screws and then I drilled and tapped 3 holes at the 2", 3" & 4" marks. I have a shop smith so I set it up to drill horizontally and made a quick jig w/ scraps to support the drilling.

I glued, nailed and screwed it together. Not shown, I borrowed my knob and bracket off of my Jamison Hollowing Rig to hold it down. I forgot to buy the iron to make one so it will do until I find myself in lowes again. You can see why I drilled 3 holes. I keep my tightening knob (1.5" piece of 1/4"x20 all-thread and a knob and some med CA) in the center and can move the other 1/4x20 bolt to the top or bottom depending on whether I need it for a smaller or larger piece. The 2nd bolt just keeps it from wondering.

I am thinking about making the final out of some sort of plastic be it PVC or UHMW. If you have an opinion on that please let me know.

My materials cost about $30 (already had the MDF). Much was unnecessary but I opened them before I realized this so I now own them.