lwalper

Member

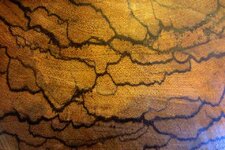

So I let (yeah, right) my wife accompany me into the local Woodcraft. They didn't have what I was looking for (a particular pen kit) so I was ready to leave ... $50 later ... I walked out with this nice piece of marblewood and some other stuff

The wood is heavily wax coated and seems to be heavy for its size. If my math is right it seems to be about 20% moisture content. I know it's a very dense wood and quite heavy anyhow, but the ratings for pounds/cf for 12% moisture content calculates out to about 20% for this chunk.

I've scraped off most of the wax -- how long is it going to take to dry out for turning? Should I cut it up and rough turn it to approximate shape or let it dry out a bit first? Just don't want it to end-check too much :frown:

The wood is heavily wax coated and seems to be heavy for its size. If my math is right it seems to be about 20% moisture content. I know it's a very dense wood and quite heavy anyhow, but the ratings for pounds/cf for 12% moisture content calculates out to about 20% for this chunk.

I've scraped off most of the wax -- how long is it going to take to dry out for turning? Should I cut it up and rough turn it to approximate shape or let it dry out a bit first? Just don't want it to end-check too much :frown:

Attachments

Last edited: