melogic

Member

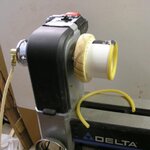

Anyone use a vacuum chuck? How do you like it? what are some pros and cons? I just purchased a Vacuum Drum Chuck head and am just a bit curious what others think of the vacuum chuck. I think it is going to be the best thing coming, especially since I'm starting to get more into bowls and platters and such! Just curious to see what others that use a vacuum chuck think of them!