I have used Alumilite Clear on carbon fiber casings but after they dry, they have white spots on them (see photo). Why is that happening and how can I get it to stop? I would appreciate it if anyone could shed some light on this problem for me.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Trouble with Carbon Fiber - help please

- Thread starter Jamie LIN

- Start date

Signed-In Members Don't See This Ad

Signed-In Members Don't See This Ad

crabcreekind

Member

Probably either moisture or ca offgassing. Are you using a pressure pot?

theidlemind

Member

Typically you want to use Silmar (or equivalent) on a "tube in" casting.

I'd rather use epoxy than ca to glue the fiber to avoid the off-gassing issues.

Check out the casting articles in the library and keep after it.

And welcome to the IAP.

I'd rather use epoxy than ca to glue the fiber to avoid the off-gassing issues.

Check out the casting articles in the library and keep after it.

And welcome to the IAP.

Trouble with Carbon Fiber

Thanks for your feedback!

To crabcreekind: No, I do not use a pressure pot. The results in my photo are after the initial coating of Alumilite to fix the fiber.

To theidlemind: Previously, I used epoxy. After it dried, I casted in poly resin. After that dried and I popped it out of the mold but when I pressed on the surface it turned white and the carbon fiber with epoxy separated from the poly resin casting???

Thanks again.

Thanks for your feedback!

To crabcreekind: No, I do not use a pressure pot. The results in my photo are after the initial coating of Alumilite to fix the fiber.

To theidlemind: Previously, I used epoxy. After it dried, I casted in poly resin. After that dried and I popped it out of the mold but when I pressed on the surface it turned white and the carbon fiber with epoxy separated from the poly resin casting???

Thanks again.

PeetyInMich

Member

If I remember correctly from the old days, some epoxies will "migrate" a wax-like substance to the surface which must be removed before recoating. Hopefully one of the guys with more experiance can chime in.

Sylvanite

Member

Humidity.

Even the tiniest amount of water will cause urethane resin to foam. If you just painted a thin coating of Alumilite Clear on the blank, then it will absorb enough moisture out of the air to bubble up before curing. Use a thicker cast, or outside heat to speed the cure. Also, to get rid of the tiny bubbles introduced when mixing, you need to put the part under pressure until it sets.

I hope that helps,

Eric

Even the tiniest amount of water will cause urethane resin to foam. If you just painted a thin coating of Alumilite Clear on the blank, then it will absorb enough moisture out of the air to bubble up before curing. Use a thicker cast, or outside heat to speed the cure. Also, to get rid of the tiny bubbles introduced when mixing, you need to put the part under pressure until it sets.

I hope that helps,

Eric

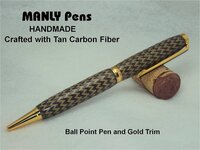

You have the worst case of this I have seen...most of the time it is just a small...small...white discoloration. I will admit...it is an elusive art...use either Silmar or PR....and i am moving to Silmar...do not use CA unless you let it sit for days to stop outgassing...do not use epoxy...as it you use too much...you will see a line where teh two meet during final turning....so....try this....I put the CF on the tube adn pull...I see you tied them...that will work...but I made a jig...that pulls the ends while in the silicon mold...plug the ends with playdoh...and plug the tube iwth playdoh so the resin does not get in the tube...heat the resin with hot water...go lean on the hardener 8 drops....so the bubble can move since heating it will cause it to set fast...three minutes if you do not...mix ..pour...and here is the tricky part...I put mine on my planer as it vibrates...and the bubble come to the top...if you pressure it...and that is ideal...you need to ensure the tube does not fill with resin....I have used dowel rods in the tube...plugged with playdoh...a bit of a pain...but you need to work with the temp and ensure you can get out all the bubbles...those really suck for a good looking fiber...look at my pic...and if you look close...there are still bubbles...you will need to tinker on that part to get the bubbles out...but you need to modify the major parts to remove all those foams....trust me...refine that process and you should be just chasing little bubbles...

Attachments

Haynie

Member

Everything I have read about Alumilite says you have to use a pressure pot.

qballizhere

Member

true....but a pressure pot with tubes is a bad idea...it iwll flood the tub...that is why you see Silmar 41 used....

I on tube cast with silmar 41 and allumilite and they are both in pressure pots. Its all in what you use. Silicone plugs work great and can be reused many times.

jttheclockman

Member

Thanks for your feedback!

To crabcreekind: No, I do not use a pressure pot. The results in my photo are after the initial coating of Alumilite to fix the fiber.

To theidlemind: Previously, I used epoxy. After it dried, I casted in poly resin. After that dried and I popped it out of the mold but when I pressed on the surface it turned white and the carbon fiber with epoxy separated from the poly resin casting???

Thanks again.

When you pressed on it it probably released itself from the tube and stated cracking or lifting thus the white spots. It also looks to me like you have a moiture problem.

You should look into getting a pressure pot to do carbon fiber only because there is so may nooks and crannys on the material and if air or moisture get into those nooks it will produce things like you see.

I use Silamar41 resin and do use a pressure pot and have had good success with Carbon fiber and other materials that have that rough texture such as braidings which I have shown here many times. Here is some CF shots.

Trouble with Carbon Fiber

Below is my latest failed attempt... Here I use Alumilite Water Clear with 15 minute working time. I put the mix in the pressure pot prior to pouring the mold to help eliminate bubbles. Then I pour the first layer in my mold and it is crystal clear. I lay the carbon fiber on top of that and cover them with more Alumilite Water Clear. Bubbles immediately begin to form. I put the mold in the pressure pot and when I take it out it looks like the bubble bath you see below. I haven't tried the planer idea yet but thanks for that tip mharvey. I appreciate your thorough explanation.

Also thanks jttheclockman - you have some great pieces there. Perhaps I should try Silmar41 next time.

Below is my latest failed attempt... Here I use Alumilite Water Clear with 15 minute working time. I put the mix in the pressure pot prior to pouring the mold to help eliminate bubbles. Then I pour the first layer in my mold and it is crystal clear. I lay the carbon fiber on top of that and cover them with more Alumilite Water Clear. Bubbles immediately begin to form. I put the mold in the pressure pot and when I take it out it looks like the bubble bath you see below. I haven't tried the planer idea yet but thanks for that tip mharvey. I appreciate your thorough explanation.

Also thanks jttheclockman - you have some great pieces there. Perhaps I should try Silmar41 next time.

Attachments

mediopolis

Member

did you ever solve your bubbles problem? If so, what did you use.

jttheclockman

Member

did you ever solve your bubbles problem? If so, what did you use.

Hello Josh, welcome to the site.

Unfortunately you resurrected a 3 year old thread and that OP is no longer posting. So maybe we can take on your question. Are you attempting to cast carbon fiber??? If so what is your method and what is the mold you are using??? What is the resin you are using??? If you are using CF how are you attaching to the tube??? Are you using a pressure pot??? Answering these questions will help in taking on your question.

mediopolis

Member

I was doing anything yet. Just learning from others mistakes a bit before trying out some CF. :biggrin:

![IMG_6240[1].jpg](/data/attachments/80/80968-a8755cb2c14cb724d32608de02f32569.jpg)

![IMG_6237[1].jpg](/data/attachments/80/80969-54e13feed2947772267adb8eb10ecb2f.jpg)

![IMG_6239[1].jpg](/data/attachments/80/80970-57e691c806d9c0d2e501f133e7947c1b.jpg)

![IMG_6328[1].jpg](/data/attachments/81/81409-6dc4dc96965ad3e54fb788e332eaf998.jpg)

![IMG_6327[1].jpg](/data/attachments/81/81410-bd289008a446b727e130349209b62724.jpg)

![IMG_6326[1].jpg](/data/attachments/81/81411-c18f0b25360624f8c308263a653f22a7.jpg)