Constant Laubscher

Member

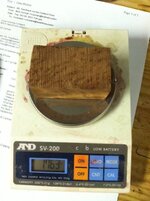

I have done a sample to do a comparison for those that think Redwood can't be stabilized. The weight increase is 157.7%

The first Photo is a piece of Natural Redwood Burl - Not Stabilized

The second photo is a piece of Dyed-Stabilized Redwood burl Look at the weight difference.

Both pieces has the same dimensions.

The first Photo is a piece of Natural Redwood Burl - Not Stabilized

The second photo is a piece of Dyed-Stabilized Redwood burl Look at the weight difference.

Both pieces has the same dimensions.

Attachments

Last edited: