jttheclockman

Member

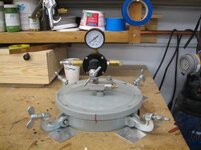

OK I want to finally put this pressure pot I got from HF about 6 months ago together and use. I know this has been talked about various times and I looked in the library for pictures but if someone can give me info as to where to find such topics or explain what I need to do from start to finish to get this pot in working order to do just pressure for i want to cast resin blanks. What parts do i need??? A picture is worth 1000 words to. I appreciate all the help and thanks in advance.