avbill

Member

I started out with buying a ‘Press Screw’ Lee Valley and Rockler has one in their catalogs. Every thing else were scrap wood from other projects. Cut 2 end pieces 4.5 x 4 x 1. I dodoed a ¾ for the base. That wood is ¾ MDF cut to 10†long. The length looks as if I need to cut it back to 7..5 inches I have only ½†threads on the press as I assembled a slim line. At the left side and end, I drill hole so the press tread could go through. 11/16†hole. I mounted the bracket to the outside. With another piece of scrap wood, I cut a 4.5 x 1.5 and mounted that piece to the other end of the Press screw. Centering it . This block of wood depth was designed so the base of the wood slides on the floor /base of vise. I took more, wood and created a gliding post on each side of vise. So the press block runs smoothly cross the vise. I had have to go buy a screw bolt what was longer than ¾†so I could tighten the screw block to the shaft of the press. I screwed the end blocks to the base of the vise together.

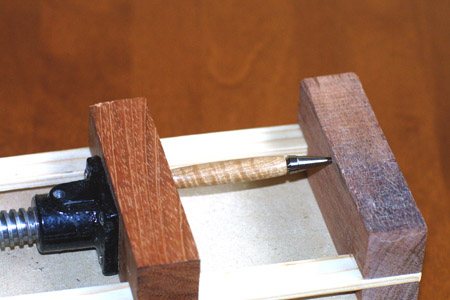

Close-up

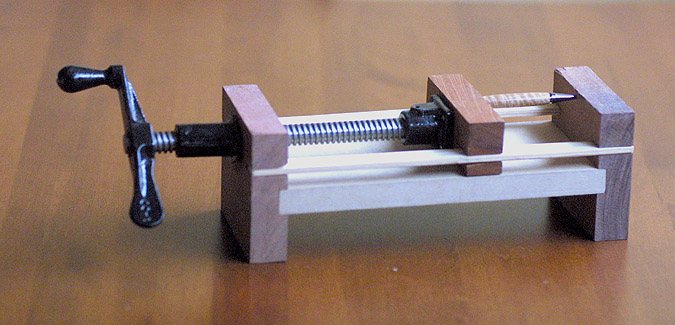

Full view

Bill Daniels [ ]

]

Close-up

Full view

Bill Daniels [