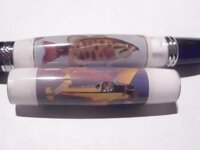

These are my first two cast blanks. A "Gone Fishing" sticker and a classic airplane stamp. I used a resin saver mold. I did not have any trouble with bubbles, but I did have what looks like some separation between the tube and the PR. You can see it in the close up of the airplane tube which has never been assembled, and near the top of the gone fishing pen. I used painted tubes from Woodcraft. The tubes were pretty glossy. I wonder If I should have scuffed the tubes or maybe paint my own. Any ideas of what might help?

Thanks

Morton

Thanks

Morton