While I wait around for taps, nibs and ebonite to arrive on the door step.

I started playing with an ink window modification, using some lexan clear tube 12.75mm od & 9.5mm id left over from a paying job.

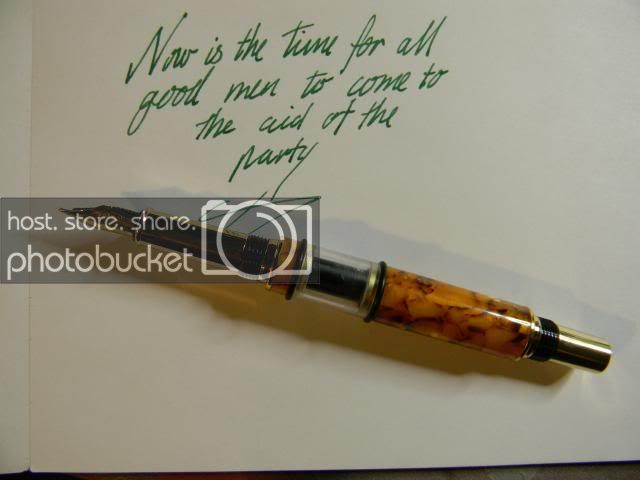

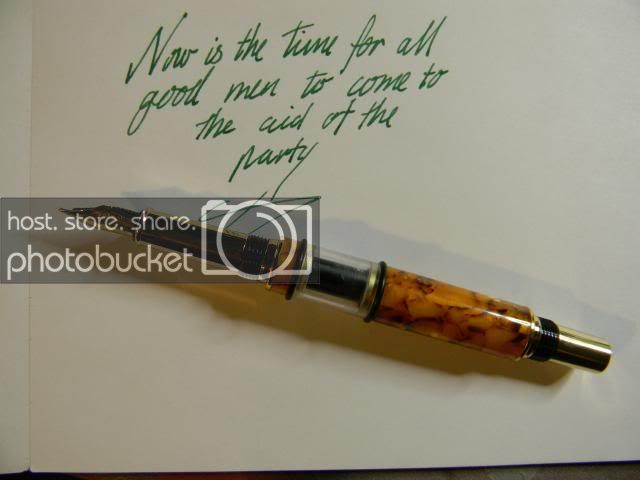

This a 'Baron II' kit in gold, here in Oz.

Any suggestions for different methods for filling and inspection window?

Here's how I went about it:

I took about 5 or 6 thou cut out of the bore for 3mm on both ends of the lexan to fit the brass tubes, with a drop of shock resistance CA to hold it together.

Turned up the bits and added a grove for some 11mm dia x 1mm o-rings....the pic shows 1.5 wall o-rings which looked a bit clunky.

Added one an o-ring to the cap as well.

Finished pen prior to filling.

A check of the tines and a wash of the feed.

and I run some 2 thou brass shim through the feed as I've found there is often some plastic flashing and crud left from the molding process which inhibits good ink flow.....then filled her up.

Fill with Noodler's forest green and did a test writing sample.....now I'll know when I'm low on ink!

I started playing with an ink window modification, using some lexan clear tube 12.75mm od & 9.5mm id left over from a paying job.

This a 'Baron II' kit in gold, here in Oz.

Any suggestions for different methods for filling and inspection window?

Here's how I went about it:

I took about 5 or 6 thou cut out of the bore for 3mm on both ends of the lexan to fit the brass tubes, with a drop of shock resistance CA to hold it together.

Turned up the bits and added a grove for some 11mm dia x 1mm o-rings....the pic shows 1.5 wall o-rings which looked a bit clunky.

Added one an o-ring to the cap as well.

Finished pen prior to filling.

A check of the tines and a wash of the feed.

and I run some 2 thou brass shim through the feed as I've found there is often some plastic flashing and crud left from the molding process which inhibits good ink flow.....then filled her up.

Fill with Noodler's forest green and did a test writing sample.....now I'll know when I'm low on ink!