Greetings everyone,

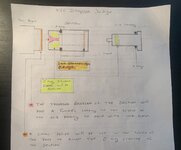

I have been researching information on fountain pen Eye Dropper designs and have not found a source of comprehensive designs and/or information on making a dedicated Eye Dropper fountain pen. I have been able to collect bits and pieces of information most of which had covered converting fountain pens designed to use converters/cartridges into Eye Dropper systems. I created a dedicated Eye Dropper design that uses two "O" rings at the shoulders of both the section and the nib housing. I plan on using "O" ring silicone grease around the threads of both the section and the nib housing to ensure I have a good seal. I also plan on cutting a small funnel shape in the tenon of the section that will lead to a small channel that is the same diameter of the nipple of the nib housing to help with ink flow.

I attached a photo of my sketch design to not only share my idea with everyone who wants to explore creating an Eye Dropper pen, but more importantly get feedback and constructive criticism from those more experienced with this type of filling system.

Thanks for looking.

Tim

I have been researching information on fountain pen Eye Dropper designs and have not found a source of comprehensive designs and/or information on making a dedicated Eye Dropper fountain pen. I have been able to collect bits and pieces of information most of which had covered converting fountain pens designed to use converters/cartridges into Eye Dropper systems. I created a dedicated Eye Dropper design that uses two "O" rings at the shoulders of both the section and the nib housing. I plan on using "O" ring silicone grease around the threads of both the section and the nib housing to ensure I have a good seal. I also plan on cutting a small funnel shape in the tenon of the section that will lead to a small channel that is the same diameter of the nipple of the nib housing to help with ink flow.

I attached a photo of my sketch design to not only share my idea with everyone who wants to explore creating an Eye Dropper pen, but more importantly get feedback and constructive criticism from those more experienced with this type of filling system.

Thanks for looking.

Tim