Dale Allen

Member

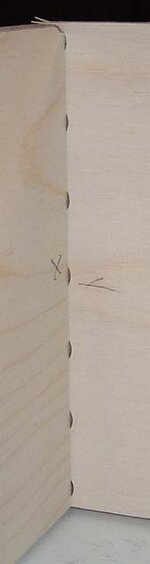

I decided to try some dovetail joints in baltic birch ply.

At this point I am not sure this is such a great idea. As you can see, there are still some voids in the layers and this came from Harville Lumber.

The ply measure .475" which of course is just shy of 1/2" by about 1/32"

I guess there is a reason the setup is for a minimum of 1/2".

The best I can do is leave small voids on the inside corner by not forcing the tails to seat.

If I cut the slots shallow, the bit does not allow me to do a climb cut prior to the finger cut and it just tears up the plywood surface.

Maybe I'm not thinking this through correctly but here's my solution, that I have yet to try.

I have some veneer that measures .038" thick.

First I put that behind the vertical piece in the PC4210 before clamping.

Then adjust the finger bar to make a slightly shallower cut, about half the .038" thickness. That way the climb cut will cut into the edge of the ply as needed and the offset of the veneer will make the tails that much shorter and should eliminate the voids on the inside.

Anyone else have any success using plywood that is not quite 1/2" thick?

At this point I am not sure this is such a great idea. As you can see, there are still some voids in the layers and this came from Harville Lumber.

The ply measure .475" which of course is just shy of 1/2" by about 1/32"

I guess there is a reason the setup is for a minimum of 1/2".

The best I can do is leave small voids on the inside corner by not forcing the tails to seat.

If I cut the slots shallow, the bit does not allow me to do a climb cut prior to the finger cut and it just tears up the plywood surface.

Maybe I'm not thinking this through correctly but here's my solution, that I have yet to try.

I have some veneer that measures .038" thick.

First I put that behind the vertical piece in the PC4210 before clamping.

Then adjust the finger bar to make a slightly shallower cut, about half the .038" thickness. That way the climb cut will cut into the edge of the ply as needed and the offset of the veneer will make the tails that much shorter and should eliminate the voids on the inside.

Anyone else have any success using plywood that is not quite 1/2" thick?