After having some fun with the 1w Chinese engraver from Gearbest, I decided to see if I could incorporate a laser onto my CNC - a project I have been thinking about for quite a while. I went with a 2w laser diode from ebay that came with a driver that could be controlled with the Mach3 software already on the machine. Using the spindle control to turn the laser on and off and the PWM capability to control the power, I now had complete control of both hardware and software and can make use of my radial axis.

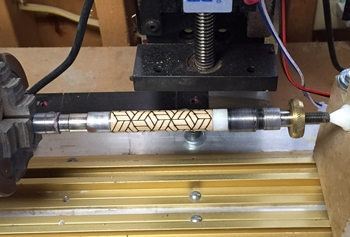

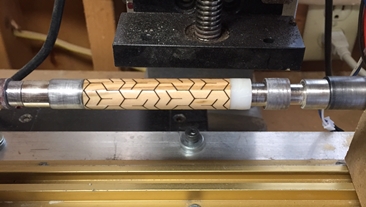

Foe vector graphics, there is a free GCode generator for InkScape from Jtechphotonics (also has great info on conversion). The picture below uses that feature. Having control, also enables me to write my own GCode, even varying the power within a file which should enable shading. Also below are 2 of my favorite patterns. All code written in Excel. This is what I call fun.

Foe vector graphics, there is a free GCode generator for InkScape from Jtechphotonics (also has great info on conversion). The picture below uses that feature. Having control, also enables me to write my own GCode, even varying the power within a file which should enable shading. Also below are 2 of my favorite patterns. All code written in Excel. This is what I call fun.