JD Combs Sr

Member

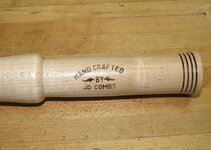

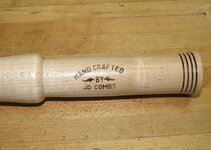

Similar to the EW 15mm carbide rougher the Pen Genie or the Woodchuck it is sized for making pens at about 16" OAL but is still very useful for making larger items. The 1/2" square shaft is cold-rolled, $9 from the local Tractor Supply hardware, the cutter, $2.61, is from Global Tooling, the 15mm radius-ed version. The handle is from a piece of 8/4 maple from my scrap bin, lets call it $2 and the ferule is a piece of 1" copper pipe from Lowe's at maybe $.25. Total monetary investment no more then $14 including the $9 for the 4ft piece of cold-rolled which I can make about 5 more of these from. Again this is a "Pen" version, I have a similar one that uses the same cuter but it is another 6-8" longer. Since I have one I made previously I made this one as a gift.

Of note:

I have recessed the cutter into the cold-rolled by about 1/4". I tend to use these tools in a skew orientation as well as scraper. Having the cutting edge more centered does not effect the scraper function but significantly improves the ability to place it into a skew orientation.

Close-ups:

I used a hack-saw to rough out the notch then use a small mill to level it and drill the screw hole.

For DIYers the notch could be dressed and leveled with a sander or grinder. I used this belt sander to round off all the sharp edges.

Comments and Critiques welcomed.

Of note:

I have recessed the cutter into the cold-rolled by about 1/4". I tend to use these tools in a skew orientation as well as scraper. Having the cutting edge more centered does not effect the scraper function but significantly improves the ability to place it into a skew orientation.

Close-ups:

I used a hack-saw to rough out the notch then use a small mill to level it and drill the screw hole.

For DIYers the notch could be dressed and leveled with a sander or grinder. I used this belt sander to round off all the sharp edges.

Comments and Critiques welcomed.